الحار منتجات

ملكنا الإخبارية

What kind of crusher is the iron striker

mclanahanWhat Type of Crusher Is Best for Primary Crushing? McLanahan

practicalmaintenance.netConstruction, Working and Maintenance of Crushers for Crushing

Removing all sizes smaller than output top size from the crusher input material. Side Liners / Cheek Plates Wear plates used to protect the crusher frame side plates. They are

文件大小: 1MBmachinerypartnerTypes of Crushers: What You Need to Know Machinery Partner

A crusher is a machine that reduces large rocks into smaller rocks, gravel, or rock dust. Crushers are mainly used in the mining and construction industries, where they are used

ScienceDirectImpact Crusher an overview ScienceDirect Topics

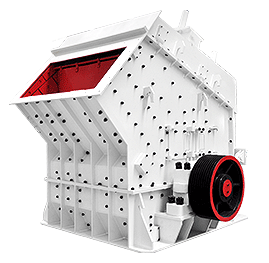

The impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum, and chemical raw materials of medium hardness.

911 MetallurgistTypes of Crushers

2015年6月23日The gyratory and jaw crushers come under the first category, the crushing rolls under the second. Strictly speaking, the gyratory motion is not a reciprocating one, but it is so with respect to any vertical

LinkedInFive Types of Crusher in the Mineral Processing

2020年9月16日According to the different crushing principle and particle size of size, the types of crusher is divided into many kinds and a variety of new types of crusher have been widely developed, mainly

agg-netUnderstanding the Different Types of Crushers Agg-Net

2018年9月10日Understanding what each crusher type is used for and knowing some general efficiency tips and the proper way to feed these machines will lead to the best results for any given site. Each type of

911 MetallurgistCrushers

2016年10月23日Crushers. It is difficult to define exactly the meaning of the terms crushing and grinding, or crushing and pulverization; the finer crushing stages may embody a certain amount of pulverizing or grinding,

ScienceDirectRoll Crusher an overview ScienceDirect Topics

Although not widely used in the minerals industry, roll crushers can be effective in handling friable, sticky, frozen, and less abrasive feeds, such as limestone, coal, chalk, gypsum,

Construction, Working and Maintenance of Crushers for Crushing

Removing all sizes smaller than output top size from the crusher input material. Side Liners / Cheek Plates Wear plates used to protect the crusher frame side plates. They are made from abrasion resistant (AR) plate (400 to 450 Brinell hardness), also called Boron steel. Top Size The largest particle size in an input or output size. Tramp Iron

Impact Crusher an overview ScienceDirect Topics

The impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum, and chemical raw materials of medium hardness. Effect of process conditions on the production capacity of crushed materials is listed in Table 8.10. This kind of crusher produces less than 20% fines,

Jaw Crushers McLanahan

H-Series Jaw Crushers still use a toggle plate that has the dual purpose of transferring the crushing action and a fuse to protect the crusher's major components. Also used are off-the-shelf bank hydraulic cylinders which provide for tramp iron relief with auto-reset to the last stored set point of the closed side setting.

Crushers 911 Metallurgist

2016年10月23日Crushers. It is difficult to define exactly the meaning of the terms crushing and grinding, or crushing and pulverization; the finer crushing stages may embody a certain amount of pulverizing or grinding,

4 Types of Stone Crushers' Maintenance and Efficient

2023年2月15日There are different types of stone crushers in mining industry such as jaw crusher, cone crusher, impact crusher, and sand making machine. This article will tell you how to maintain the 4 types of

Types of Stone Crushers Machine Mineral Processing

2020年7月10日It can crushers iron ore, Quartz Stone, rock gold, rock tantalum niobium ore, rock tin ore, rock tungsten ore, manganese ore, ilmenite ore, K-albite, limestone, river pebbles, copper ore, bauxite,

Impact Crusher Blow Bars The Ultimate Guide RUBBLE MASTER

Impact crusher blow bars (also called hammers) are the main wear item of horizontal shaft impact crushers and a major cost driver. The purpose of blow bars is to strike material entering the crushing chamber and throwing it against the impact wall causing the material to fracture into smaller particles (see also: how does an impact crusher work).In the

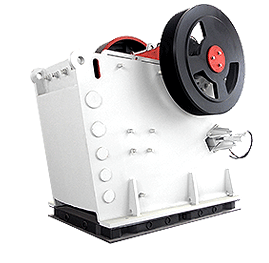

Jaw crusher InfoVis:Wiki

Jaw crusher introduction. Jaw crusher, also named jaw crushing machine or jaw breaker is the world's most ancient form of stone crusher or rock crusher. Jaw crusher's main part is jaw crushing chamber composed of dynamic crusher jaw and static crusher jaw crusher simulating jaw movement of animals to complete the stone material crushing operations.

Fire striker Wikipedia

A fire striker is a piece of carbon steel from which sparks are struck by the sharp edge of flint, chert or similar rock. [1] [2] [3] It is a specific tool used in fire making . History [ edit] Before the invention of matches, percussion fire making was often used to start fires.

what are the equipment in iron ore crusher? LinkedIn

2023年2月13日. . . . what are the equipment in iron ore crusher? Iron ore crushers are important equipment for iron ore processing. The most commonly used iron ore crushers are jaw crusher, cone...

practicalmaintenance.netConstruction, Working and Maintenance of Crushers for Crushing

Removing all sizes smaller than output top size from the crusher input material. Side Liners / Cheek Plates Wear plates used to protect the crusher frame side plates. They are made from abrasion resistant (AR) plate (400 to 450 Brinell hardness), also called Boron steel. Top Size The largest particle size in an input or output size. Tramp Iron

ScienceDirectImpact Crusher an overview ScienceDirect Topics

The impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum, and chemical raw materials of medium hardness. Effect of process conditions on the production capacity of crushed materials is listed in Table 8.10. This kind of crusher produces less than 20% fines,

mclanahanJaw Crushers McLanahan

H-Series Jaw Crushers still use a toggle plate that has the dual purpose of transferring the crushing action and a fuse to protect the crusher's major components. Also used are off-the-shelf bank hydraulic cylinders which provide for tramp iron relief with auto-reset to the last stored set point of the closed side setting.

911 MetallurgistCrushers

2016年10月23日DOUBLE-TOGGLE JAW CRUSHER. The double-toggle mechanism, patented in 1858 by Mr. E. W. Blake, remains unrivalled for all units of exceptional power and size. Fig. 1 is a cross section of an early

LinkedInWhat equipment is used in iron ore crusher?

2023年2月17日Jaw Crusher: This is a primary crusher that is used for coarse crushing. It has a fixed jaw plate and a movable jaw plate, and the material is crushed between them. 2. Cone Crusher: This is...

ftmmachineryCharacteristics and Comparison of Four Types of Jaw

2023年2月15日Mobile jaw crusher: High mobility determines that it is suitable for frequent conversion of crushing sites (like road construction, urban construction waste disposal, etc).Thus, its price is higher than

mineraldressingTypes of Stone Crushers Machine Mineral Processing

2020年7月10日It can crushers iron ore, Quartz Stone, rock gold, rock tantalum niobium ore, rock tin ore, rock tungsten ore, manganese ore, ilmenite ore, K-albite, limestone, river pebbles, copper ore, bauxite,

LinkedInWhat equipment is used to extract iron ore

2023年2月24日1.Crushers: These machines are used to break down large pieces of ore into smaller pieces that can be processed more easily. 2.Conveyors: Once the ore has been broken down, it needs to be...

infovis-wiki.netJaw crusher InfoVis:Wiki

Jaw crusher introduction. Jaw crusher, also named jaw crushing machine or jaw breaker is the world's most ancient form of stone crusher or rock crusher. Jaw crusher's main part is jaw crushing chamber composed of dynamic crusher jaw and static crusher jaw crusher simulating jaw movement of animals to complete the stone material crushing operations.

rubblemasterImpact Crusher Blow Bars The Ultimate Guide RUBBLE MASTER

Impact crusher blow bars (also called hammers) are the main wear item of horizontal shaft impact crushers and a major cost driver. The purpose of blow bars is to strike material entering the crushing chamber and throwing it against the impact wall causing the material to fracture into smaller particles (see also: how does an impact crusher work).In the

موتر كسارة الصخور

النبذة عن manufacturiing محطم

شركة المطاحن والأعلاف المستندات المطلوبة للتسجيل

مصنع لصناعة شاشات ال سي دي

أهداف صناعة الأسمنت تورورو

الأجزاء الأساسية من الحزام

الطب محطم وعاء الرخام

قدم مخروط محطم المثل

مطحنة الباريت على جرافة

تكلفة كسارة الحجر في صناعة تكسير الحجر

و

النظام الهيدروليكي كسارة لفة

tabel harga penggiling top di chennai

الهند منخفضة التكلفة آلة غسل الرمال

مصنع تكسير خام الحديد تصدير الجهاز إلى سعر كولومبيا

تم توفير معدات الأسمنت

تحليل حجر كسارة الحجر

أسعار محطم زنزيتي مخروط

أنواع المعادن الصناعية

تجزئه محركات المكائن الثقيله الشفل الكاوسكي

تقاضا برای شستن مواد معدنی و کارخانه فرآوری در هند

المحمول شراء كسارة

المخروط المطحنة التكليف قائمة

شريط L T ضربة تستخدم في مصنع للاسمنت في الهند

انواع الكسارات السن مير

كسارة الحجر الجيري من infomation

حول لدينا

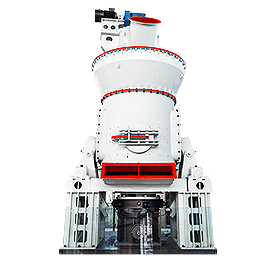

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20