الحار منتجات

ملكنا الإخبارية

Feasibility report for the development of floating bead fly ash

Effect of floating bead on the manufacturing process of fly ash

2019年6月29日The influence of the characteristics of floating beads on the properties of fly ash ceramics was Effect of floating bead on the manufacturing process of fly ash ceramics Qi 2020 International Journal of Applied Ceramic Technology Wiley

Effect of floating bead on the manufacturing process of fly ash

2019年6月29日The influence of the characteristics of floating beads on the properties of fly ash ceramics was discussed. The best sintering conditions were determined through

(PDF) Effect of Floating Bead on the Manufacturing Process of Fly

2019年6月29日Qi et al. (2019b) have demonstrated that the particle size of floating beads can be used as a regulating factor for the sintering of CFA-based ceramics and

Effect of floating bead on the manufacturing process of fly ash

2019年6月29日Abstract. A new type of ceramic material was prepared by adding flux with floating beads and kaolin. The influence of the characteristics of floating beads on the

Fly ash properties, characterization, and applications: A

2021年9月1日Fly ash (FA) is the principal industrial waste byproduct from the burning of solid fuels. FA is a powdery solid that is constituted mostly of unburned carbon (UC),

Evaluating the Performance and Feasibility of Using Recovered Fly

This study evaluates the feasibility, performance, and beneficiation of two alternative and abundant sources of fly ash: recovered landfilled fly ash and fluidized bed combustion

Evaluating the Performance and Feasibility of Using Recovered Fly

Feasibility of Using Recovered Fly Ash and Fluidized Bed Combustion (FBC) Fly Ash as Concrete Pozzolan By: Farshad Rajabipour, Ph.D., F.ACI Mona Zahedi, Ph.D.

modified Fly Ash Floating Bead/polyaniline Composites

Abstract: Fly ash floating bead (FAFB) was modified by the nonionic surfactant polyethylene glycol (PEG) under various concentrations to improve its hydrophobility, and then PEG

For Peer Review ResearchGate

1 000℃ . 1 100℃ . 1 200℃. Microstructure of materials at different sintering temperatures. Effect of Floating Bead on the Manufacturing Process of Fly Ash Ceramics. Liqiang

For Peer Review ResearchGate

For Peer Review Effect of Floating Bead on the Manufacturing Process of Fly Ash Ceramics Liqiang QIa,b*, Fei TENGa, Kunyang LIUa, Yajuan ZHANGa a Hebei Key Lab

A feasibility study of strain hardening fiber reinforced fly ash

2014年4月30日The ratio is in terms of weight of the ingredients, except for the fiber that is expressed in terms of volume fraction. Two types of fly ash were used in this study, labeled Fly ash A and B, respectively. Fly ash A was obtained from Headwaters Resources and Fly ash B from Lafarge. Both are classified as class F fly ash as designated by ASTM C 618.

modified Fly Ash Floating Bead/polyaniline Composites

Abstract: Fly ash floating bead (FAFB) was modified by the nonionic surfactant polyethylene glycol (PEG) under various concentrations to improve its hydrophobility, and then PEG modified FAFB composited with polyaniline (FAFB-PEG/PAn) by emulsion polymerization method using different feed ratios of FAFB- PEG.

Effectiveness of Expanded Polystyrene (EPS) Beads Size on Fly Ash

2020年3月9日Different sizes of EPS beads were mixed with fly ash to study the effect on maximum dry unit weight, cohesion, angle of internal friction, California bearing ratio (CBR) value, coefficient of consolidation, and permeability.

Comprehensive Utilization of Fly Ash SpringerLink

2019年5月23日The grain size of drift bead is relatively large in spherical particles with diameter of 30–100 μm and wall thickness of 0.2–2 μm. As the walls of drift beads are thin and fragile, only a small amount of bead fragments are found in fly ash sample. The percentage of drift beads in fly ash is about 0.5–1.5%. 2. Solid bead (sinking bead)

TECHNO ECONOMIC FEASIBILITY REPORT ON FLYASH BRICKS”

This Techno-Economic Feasibility Report has been prepared on the basis of information available. The intention here is to provide preliminary information to the prospective entrepreneur.

(PDF) A study on economic feasibility of fly ash and ground

2021年3月1日To mitigate this crisis, Geopolymer concrete (GPC) which constitutes industrial wastes like Ground Granulated Blast Furnace Slag (GGBS), flyash, limestone husk is considered as a more eco-friendly and...

Feasibility study on the development of fly ash bricks utilizing

2021年9月23日Feasibility study on the development of fly ash bricks utilizing vermicompost as an alternate material for M sand. Authors: K. S. Ajay Venkadesh. K. Harish Kumar. B. Hariharan. A. Arumugam....

Feasibility of using fly ash admixtures in landfill bottom liners

2008年12月15日Fly ash amended with up to 20% lime satisfied the hydraulic conductivity requirement of less than 1×10 ‐7 cms ‐1. However, lime‐fly ash becomes brittle with age. The resultant inflexibility will produce cracks when subjected to differential loading and settlement conditions at landfill sites.

Development of Light Weight Geoblocks for Wall ResearchGate

feasibility of using a significant portion of fly-ash and EPS beads for beneficial purpose in civil engineering applications that is cost effective and environmentally friendly.

Feasibility Study of Fly Ash as a Replacement for Fine Aggregate

higher strength for a given density, as fly ash is of pozzolonic nature. M. Potha Raju [2] Investigated the changes in flexural strength of fly ash concrete under elevated temperature of 100°C, 200°C and 250°C for 1 hour,2 hour, and 3 hours duration. The results showed that the fly ash content upto 20% showed improved performance

A feasibility study of strain hardening fiber reinforced fly ash

2014年4月30日The ratio is in terms of weight of the ingredients, except for the fiber that is expressed in terms of volume fraction. Two types of fly ash were used in this study, labeled Fly ash A and B, respectively. Fly ash A was obtained from Headwaters Resources and Fly ash B from Lafarge. Both are classified as class F fly ash as designated by ASTM C 618.

Technical Assistance Consultant’s Report Asian Development

Technical Assistance Consultant’s Report Project Number: 49019-001 December 2017 People's Republic of China: Sustainable Management of Fly Ash from Municipal Solid Waste Incineration Prepared by the China Urban Construction DesignResearch Co., Ltd. 4.4.2 The Development of and Problems Faced by the Treatment and Disposal

Effectiveness of Expanded Polystyrene (EPS) Beads Size on Fly Ash

2020年3月9日Different sizes of EPS beads were mixed with fly ash to study the effect on maximum dry unit weight, cohesion, angle of internal friction, California bearing ratio (CBR) value, coefficient of consolidation, and permeability.

Classification and Milling Increase Fly Ash Pozzolanic Reactivity

Upcycling and reclaiming of low quality or stored coal combustion fly ashes could enable to tap into a voluminous resource of supplementary cementitious materials (SCMs) for low-carbon blended cements. Low reactivity fly ashes are usually either too crystalline or too coarse. Beneficiation treatments for coarse fly ashes comprise size classification or

Comprehensive Utilization of Fly Ash SpringerLink

2019年5月23日The grain size of drift bead is relatively large in spherical particles with diameter of 30–100 μm and wall thickness of 0.2–2 μm. As the walls of drift beads are thin and fragile, only a small amount of bead fragments are found in fly ash sample. The percentage of drift beads in fly ash is about 0.5–1.5%. 2. Solid bead (sinking bead)

Feasibility study on the development of fly ash bricks utilizing

2021年9月23日The high amount of calcium oxide present in the fly ash makes it suitable for use in the construction for pillars, foundation and also in the construction of walls [ 1] Development of bricks by using bottom ash and fly ash is considered a more feasible solution than the conventional clay bricks because of its lower cost, eco-friendly and

Feasibility of using fly ash admixtures in landfill bottom liners

2008年12月15日Fly ash amended with up to 20% lime satisfied the hydraulic conductivity requirement of less than 1×10 ‐7 cms ‐1. However, lime‐fly ash becomes brittle with age. The resultant inflexibility will produce cracks when subjected to differential loading and settlement conditions at landfill sites.

Recycling of fly ash for development of value added products

2021年1月1日The main objectives designed for the present work are (i) effective use of fly ash for development of membranes and bricks, and (ii) optimization of bricks making raw materials composition by d-optimal mixture model in Response Surface Methodology. 2. Materials and methods. 2.1. Membrane manufacturing and testing methods.

Development of nanosilver-coated geopolymer beads (AgGP) from fly ash

Fly Ash obtained from a coal-fired power plant in Central Luzon and waste Baluko shells collected from Sorsogon, Bicol were used as the raw materials for the geopolymer beads, while 12 M NaOH and water glass solution (WGS) (SiO2/Na2O = 2.4) formed the

Feasibility Study of Fly Ash as a Replacement for Fine Aggregate

higher strength for a given density, as fly ash is of pozzolonic nature. M. Potha Raju [2] Investigated the changes in flexural strength of fly ash concrete under elevated temperature of 100°C, 200°C and 250°C for 1 hour,2 hour, and 3 hours duration. The results showed that the fly ash content upto 20% showed improved performance

مصنع معالجة الفحم karaganda cci

سنگ مس فلز متخلخل به عنوان مواد سلولی فلوتاسیون طلا

أذربيجان آلات التعدين الذهب والمعدات

تجهيز التعدين ليمبوبو

سنگ شکن 10tph آفریقای جنوبی

مقاييس طاحونة أنبوب خام التعدين لفة

ریموند محرک سوپاپ سیستم کنترل

الحد من نسبة تخفيض على الكسارات المنتج

ماشین آلات سنگ شکن چکش سنگین برای فروش

كربونات الكالسيوم الخشنة

أفضل سعر المفرق الحديد خام تهتز الشاشة

جعل اسمي على الرمال

چگونه برای ساختن یک سنگ آسیاب مقوا

مطحنة الاسمنت العمودية الجديدة

الغريني معدات التعدين الذهب يوتا

وظيفة ناقل مطحنة الكرة

تايلند القصدير خام معدات التعدين المورد

حصان مصنعي مطحنة الفحم في الهند

أسود البورون معدات القصدير

قائمة أسعار مطحنة المطرقة

کالیبراتور غربال ارتعاشی

مطحنة الأسمنت اليد الثانية سري لانكا

سعر كسارة الصخور 150 Tph في الهند

المحمول flotaton خلية نبات الحجر الحجر

قاعدة مطحنة الخرسانة ريموند

مطحنة مطرقة صغيرة ذات جودة عالية

حول لدينا

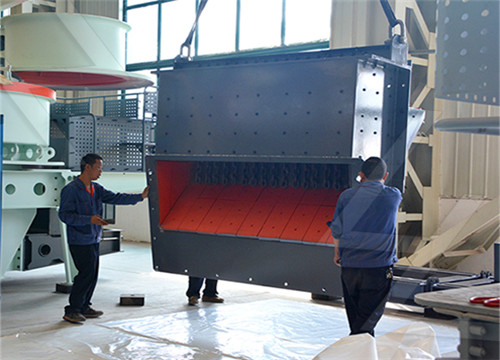

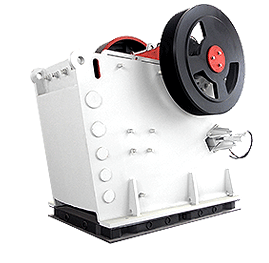

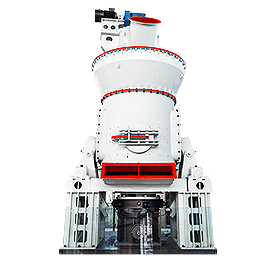

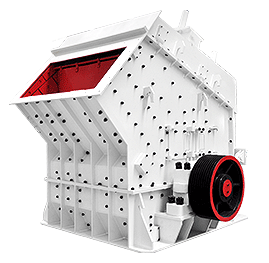

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20