الحار منتجات

ملكنا الإخبارية

process for making boehmite alumina

Structure of boehmite-derived γ-alumina and its

2021年8月4日Two kinds of boehmite to γ-alumina transformation mechanisms, namely collapse and reaction mechanisms, were elucidated crystallographically in detail with

Production of micro-crystalline boehmite from

2013年2月1日The most common techniques to produce boehmite are via hydrothermal digestion of different types of ATH or seeded precipitation from sodium aluminate (Bayer

Boehmite Process: An Alternative Technology in Alumina

2001年2月1日Boehmite process is an innovative variation of the current Bayer process for the production of smelter grade alumina. The claimed

(PDF) Boehmite Process-A new approach in alumina

2002年1月1日The Bayer process for the production of alumina consists of three main stages: bauxite digestion with sodium hydroxide solution at

Boehmite Process A New Approach in Alumina Production

The Boehmite process is a novel variation of the Bayer proc- ess. The novelty of this process is related to the production of pure crystalline Boehmite, alumina

Process for making boehmite alumina, and methods for making

Abstract. This invention comprises a novel process for making boehmite alumina and comprises selecting an alumina, and heating it in the presence of an alkali metal

Bayer Process: Manufacturing Of Alumina Making of

Alumina is the main components of bauxite, so bauxite is refined in order to produce Alumina. The Bayer process is the principal way for producing alumina by refining Bauxite. Bauxite other than with 30-60percentage of

Preparation and Properties of Pseudo-boehmite Obtained

2018年12月17日A sintering CO 2 decomposition process for preparation of pseudo-boehmite is proposed for clean valorization of high-alumina fly ash. The effects of

Method for making modified boehmite alumina Google Patents

According to one aspect of the present invention, there is provided a process for making a modified boehmite alumina wherein an aqueous slurry of a boehmite alumina is

Production of micro-crystalline boehmite from ScienceDirect

2013年2月1日The most common techniques to produce boehmite are via hydrothermal digestion of different types of ATH or seeded precipitation from sodium aluminate (Bayer process) liquors. Mehta and Kalsotra [7] found that the hydrothermal transformation of gibbsite to boehmite starts at 190 °C with slow kinetics and is completed at 250 °C.

Boehmite Process: An Alternative Technology in

2001年2月1日Boehmite process is an innovative variation of the current Bayer process for the production of smelter grade This process if developed would reduce the energy consumption for making alumina.

Production of micro-crystalline boehmite from ScienceDirect

2013年2月1日A hydrothermal leaching process was developed to produce fire retarding micro-boehmite (4–25 mm) using plant aluminium hydroxide (alumina trihydate, ATH) (< 50 mm in mean size). Well crystalline product of high purity (< 0.05% Na 2 O and < 0.01% Fe 2 O 3) and whiteness (rating 97.8) could be produced at > 200 °C, 1–2 MPa after 1 hour.

Boehmite Process A New Approach in Alumina Production

Dimitrios Panias et al.: Boehmite Process A New Approach in Alumina Production 6] have shown that pure crystalline boehmite can be iso- thermally precipitated at temperatures as low as 90 °C

Two-Stage Process for Precipitating Coarse Boehmite from Sodium

2017年8月1日To increase the precipitation rate significantly and obtain sandy alumina, a two-stage seeded precipitation process for preparing coarse boehmite was studied. In the first stage, which involved gibbsite precipitation, the fresh fine gibbsite, along with the active seed of less than 20 g L−1, acted as seed. An estimated 70% precipitation rate was

Innovative Process for Boehmite Precipitation in Bayer Circuit

2019年8月21日The Bayer process is globally employed as the most important route to produce alumina from bauxite. Precipitation of crystalline aluminium trihydroxide from supersaturated sodium aluminate liquor is one of the main steps in the Bayer process.

Synthesis of high quality boehmite and γ-alumina for phosphorus

2022年9月1日A facile ball milling process was used to obtain mesoporous crystalline γ-alumina with high specific surface area up to 389 m 2 g −1 and large pore volume up to 1.55 cm 3 g −1 from boehmite. First boehmite particles were efficiently dispersed into small nanocrystals, which was achieved by using ball milling with addition of a small amount of

Boehmite an overview ScienceDirect Topics

Production. The production of β alumina powder is based on the boehmite route. The boehmite (aluminum oxide monohydrate Al2 O 3 H 2 O) is calcined at around 800 °C in an indirect, gas-fired, rotary calciner in which a metal tube is heated from the outside.

Bayer Process: Manufacturing Of Alumina Making of

The Bayer process is the principal way for producing alumina by refining Bauxite. Bauxite other than with 30-60percentage of aluminium oxide contains mixture of silica, iron oxides and titanium dioxide. Bayer

Method for making modified boehmite alumina Google Patents

A process for making a modified boehmite alumina comprising reacting at elevated temperatures a boehmite alumina with a compound having the formula:wherein X is an organic moiety, M in a monovalent cation, and n is an integer reflecting the number of SO3M groups bonded to said organic moiety to produce a reaction mixture containing modified

Production of micro-crystalline boehmite from ScienceDirect

2013年2月1日The most common techniques to produce boehmite are via hydrothermal digestion of different types of ATH or seeded precipitation from sodium aluminate (Bayer process) liquors. Mehta and Kalsotra [7] found that the hydrothermal transformation of gibbsite to boehmite starts at 190 °C with slow kinetics and is completed at 250 °C.

Boehmite Process: An Alternative Technology in

2001年2月1日Boehmite process is an innovative variation of the current Bayer process for the production of smelter grade alumina. The claimed innovation of this process concerns the precipitation and...

Structure of boehmite-derived γ-alumina and its transformation

Keywords: alumina; boehmite; crystal structure; electron diffraction; quantitative microscopy; transformation mechanism. CCDC reference: hydrogen bond chain in boehmite. This process results in the formation of voids or pores, without the need for layers to collapse. This mechanism was also proposed for other struc-

Effects of Different Raw Materials in the Synthesis of Boehmite and

2016年11月10日Two alumina polymorphs, the metaestable γ -Al 2 O 3 and the stable α -Al 2 O 3,were obtained from thermal treatment of the precursor γ -AlOOH (boehmite). This precursor was prepared by a precipitation method employing different raw materials in order to study their effect on the synthesis process and several characteristics of the

Boehmite Process A New Approach in Alumina Production

ERZMETALL 56 (2003) Nr. 2 77 Dimitrios Panias et al.: Boehmite Process A New Approach in Alumina Production creases from 230 g/L (normal precipitation) to 1200 g/L

Two-Stage Process for Precipitating Coarse Boehmite from Sodium

2017年8月1日To increase the precipitation rate significantly and obtain sandy alumina, a two-stage seeded precipitation process for preparing coarse boehmite was studied. In the first stage, which involved gibbsite precipitation, the fresh fine gibbsite, along with the active seed of less than 20 g L−1, acted as seed. An estimated 70% precipitation rate was

Synthesis of high quality boehmite and γ-alumina for phosphorus

2022年9月1日A facile ball milling process was used to obtain mesoporous crystalline γ-alumina with high specific surface area up to 389 m 2 g −1 and large pore volume up to 1.55 cm 3 g −1 from boehmite. First boehmite particles were efficiently dispersed into small nanocrystals, which was achieved by using ball milling with addition of a small amount of

Alumina from reprocessing of spent hydroprocessing catalyst

2011年12月15日In the present study, both boehmite and γ-Al O were obtained by reprocessing spent hydroprocessing catalysts and their textural properties were modified by hydrothermal treatment to obtain large surface area (>200 m /g), pore volume (>0.7 ml/g), and desirable pore size distribution.

Process for preparing dispersible boehmite alumina

2017年6月9日A process for the preparation of finely divided dispersible alpha-alumina monohydrate (boehmite) from alumina trihydrate is disclosed. The alumina trihydrate is calcined thereby...

Method for making modified boehmite alumina Condea Vista

A process for making a modified boehmite alumina comprising reacting at elevated temperatures a boehmite alumina with a compound having the formula: X(SO 3 M) n. wherein X is an organic moiety, M in a monovalent cation, and n is an integer reflecting the number of SO 3 M groups bonded to said organic moiety to produce a reaction mixture

VSI محطم قطع الغيار قائمة جزء

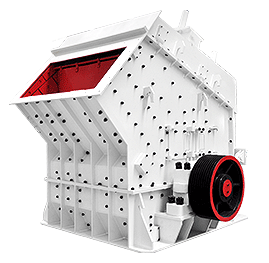

المطرقة محطم المطرقة مطحنة تأثير المطرقة محطم عرض

الرسم ومواصفات كسارة

صور الحجر المسحوق في دبي

قسم الأصفر مطحنة الصناعية بازوكا الهاتف كولياكان

المسمار نقل الشرائح

ينيكها الجارية سراويله

انتاج المطاحن والكسارات في العراق

تنگستن سپرده سندرز قیمت در هند

معدات الكسارات في ألمانيا

مصنعي مصنفات الرمل في مصر

الفرق بين كسارة مخروطية وكسارة مخروطية

تأثير جيد جودة تأثير محطم كسارة الصخور كسارة للبيع

عنوان شركات صينية في الجزائر

تفاصيل وحدات تكسير الدولوميت

محطة كسارة المحمول باركر

تطبيق كسارة الحجر بتكلفة 40 طن في الساعة

أجزاء مطحنة الخام العمودية

والشركة المصنعة العرض في أستراليا

محطم دلو لتوظيف أستراليا

اسعار ماكينة تصنيع النشارة

نوع من كسارة مخروطية الزنبرك والهيدروليكية

germany calcium carbonate grind mill

شركة عمر قاسم العيسائي للمعدات الثقيل

قرطاسية صخور مطحنة الولايات المتحدة الأمريكية

manufacturers suppliers 487

حول لدينا

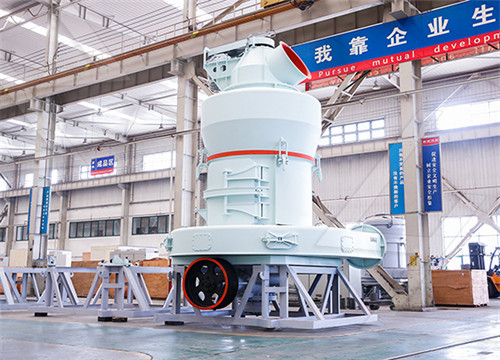

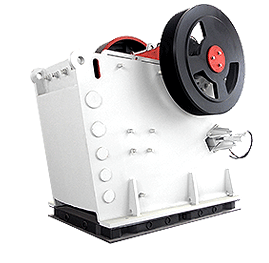

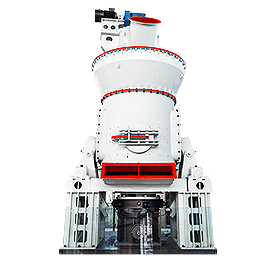

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20