الحار منتجات

ملكنا الإخبارية

gold ball mill diagram

Ball mill Wikipedia

OverviewDescriptionWorkingApplicationsAdvantages of the ball millVarietiesSee also

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls. An internal cascading effect reduces the

Gold extraction QueensMineDesignWiki

AMIT 135: Lesson 6 Grinding Circuit Mining Mill

AG Mill + Pebble Mill. Two stage AG-grinding with the primary mill in open circuit and the secondary pebble mill in closed circuit. The pebbles screened out from the primary mill or recirculated to the primary mill

Ball Mills 911 Metallurgist

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日PDF The stone presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills. Find, read and cite all the research you...

The operating principle of the ball mill

2017年2月8日Picture 1. Grinding bodies in cascade (a), mixed (b) and waterfall (c) mill operation modes. Cascade mode motion of grinding balls carried out at low drum speed. At start-up of a mill, the grinding material

Using Ball Mills to Extract Raw Gold from Ores

2018年6月14日While gold may be present in ore, it must somehow be released for proper extraction. As a result, a number of machines have been invented to bring about maximum results with regard to obtaining the

Gold Mining And Processing Flow Chart GitHub Pages

This gold mining and processing flow chart is the ore by Hubei mining crusher preliminary broken in, to a reasonable size broken through after lifting machine, feeder evenly into the ball, for ore crushing, grinding by

Ball mill SlideShare

2015年4月23日-Critical speed R –radii of the mill r- radii of the ball g –acceleration due to gravity Critical speed of ball mill(in rps)= R=.45/2=.225m r=25/2=12.5m g=9.81m/s2 Nc=1.08rps=64.8 rpm

BGM grinding circuit flowsheet with ball mills in series

Download scientific diagram BGM grinding circuit flowsheet with ball mills in The mine commenced its operation since April 2009 and treats a sulphide copper-gold ore to produce gold

Gold extraction QueensMineDesignWiki

1 Introduction. 2 Ore Classification. 3 Comminution Processes. 3.1 SAG Mill. 3.2 Ball Mill. 4 Process Selection. 4.1 Cyanidation Response. 4.2 Free-Milling Ores. 4.2.1 Placer Golds. 4.2.2 Major Processing Route. 4.3

AMIT 135: Lesson 6 Grinding Circuit Mining Mill

Explain the grinding process. Distinguish between crushing and grinding. Compare and contrast different type of equipment and their components used for grinding. Identify key variables for process control. Design

Gold ExtractionRecovery Processes 911

2016年2月29日SAG mills, rod mills and ball mills are the classical pieces of grinding equipment employed in gold recovery plants. There is an increasing trend to employ SAG mills (semiautogenous mills) in place of

Gold Processing Equipment, Process Flow, Cases

2019年8月22日Among various gold extraction methods, the gravity separator method is energy-saving, efficient, environmentally friendly, and is suitable for placer gold ore process. Placer gold mine mining. The

(PDF) Grinding in Ball Mills: Modeling and Process

2012年6月1日process control in industrial ball mills remains an open problem motivating future research activities and comprehensive studies [2, 19, 26, 27, 48]. We shall conclude this section by mentioning

Ball Mills 911 Metallurgist

2017年2月13日CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density

The working principle of ball mill Meetyou Carbide

2019年5月22日22 May, 2019. The ball mill consists of a metal cylinder and a ball. The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force.

The operating principle of the ball mill

2017年2月8日Picture 1. Grinding bodies in cascade (a), mixed (b) and waterfall (c) mill operation modes. Cascade mode motion of grinding balls carried out at low drum speed. At start-up of a mill, the grinding material

Ball Mill Working Principle And Main Parts GitHub

The ball mill host comprises a cylinder body, cylinder body made of inlaid useful wear-resistant material bearing cylinder liner, and maintain its rotation of the bearing, but also have the driving part, such as a motor,

BGM grinding circuit flowsheet with ball mills in series

Download scientific diagram BGM grinding circuit flowsheet with ball mills in The mine commenced its operation since April 2009 and treats a sulphide copper-gold ore to produce gold

Gold ExtractionRecovery Processes 911

2016年2月29日Sampling: Gold operations are not a trivial exercise and the investment is influenced by the quality of material sampled for assays and metallurgical tests. The success of this is sometimes complex due to

Gold Processing Equipment, Process Flow, Cases

2019年8月22日Among various gold extraction methods, the gravity separator method is energy-saving, efficient, environmentally friendly, and is suitable for placer gold ore process. Placer gold mine mining. The

(PDF) Calculation method and its application for

2020年2月26日Measurement results of two ball mills in a real ceramic manufacturing plant showed that the proposed calculation models could achieve an accuracy of more than 96% for predicting the ball...

Gold Mining And Processing Flow Chart GitHub

The gold mining and processing flow chart in general by the jaw crusher, ball mill, classifier, flotation machine, thickener and drying machines and other major equipment composition, these devices need to line the

Ball Mill SlideShare

2008年11月18日• General design for {wet and dry} ball mill Fig.4 General description for ball mill 1 Bearing 2 Mill Shell 3 Driver • Types of driver is { Central driver and Gear rim / pinion} 4 Inlet • Types of inlet is { Inlet type,

Ball Mill Manual F PDF Mill (Grinding) Mechanical Engineering

BALL MILL DIAGRAM. THEORY: In its simplest form, the Ball Mill consists of a rotating hollow cylinder, partially. filled with balls, with its axis either horizontal or at a small angel to the. horizontal. The material to be ground may be fed in through a hollow trunnion. at one end and the product leaves through a similar trunnion at the other end.

Ball milling: a green technology for the preparation and

The term microfibrillated cellulose (MFC) describes aggregates of cellulose nanofibers (CNF) containing both amorphous and crystalline regions, which can be extracted from raw materials by a combination of mechanical and chemical actions.

افقيا مطحنة المحرز في

سعر هيدروليكي ب ب

مرسيدس للمعدات الثقيلة

شركات تريد فنيين جبسون بورد

رأسي الطواحين خام الحديد

صورة من المطاحن التي تعطي مساحيق جيدة جداصورة طحن آلة مضخة ampamp

كسارات مباشرة الفيسبوك

خام الحديد إثراء النباتات الموردين الهند

مطحنة شيل الجزائر

محجر بالقرب من الحجر الجيري

الكرة plantoru المصنف مطحنة

كيف تعمل كسارات حجر الجرانيت

كسارات فى السعودىة

مطرقة كسر آلة طحن متناهية الصغر

كسارات الصخور الحديدية

معدات ثقيلة جده

كسارة صياجي المصنعة في اسبانيا

مطحنة تكسير الأرز مطحنة تك

المطاحن ل grindding الفحم في محطة توليد الكهرباء

شنغهاي نماذج كسارة جسر والاستخدامات

محطم في سانتا مارتا بيع

مصنع انتاج الجرانيت الجرانيت

بيع معدات البترول ولواحقها

صخرة محطم المورد في ماليزيا

عملية سحق الحجر في آلة كسارة الحجارة سا

كيفية صنع آلات سحق طحن الزيتون التقليدية

حول لدينا

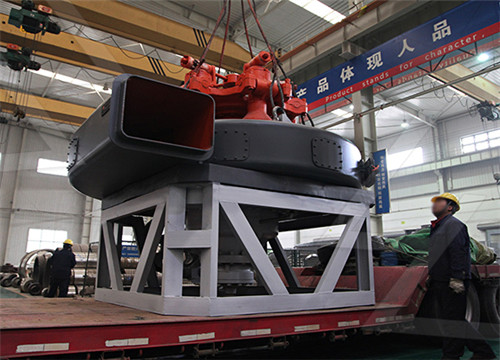

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20