الحار منتجات

ملكنا الإخبارية

all egories ball mill

Ball Mill RETSCH powerful grinding and homogenization

RETSCH offers the largest selection of laboratory ball mills in the market! Ball mills are among the most variable and effective tools when it comes to size reduction of hard,

进一步探索Laboratory Ball Mill, 5 Kg Capacity, 10 Kg Capacity, 20 Kg The right laboratory ball mill for each grinding task RETSCHCalculate and Select Ball Mill Ball Size for Optimum How to Make a Ball Mill: 12 Steps (with Pictures) wikiHowBall Mill Grinding Theory Crushing Motion/Action Inside

Ball Mill at Thomas Scientific

High-energy ball mill with dual clamps that accommodates sample sizes ranging from 0.2 10 grams. Ideal for grinding dry, brittle samples, mechanical alloying, slurry grinding,

进一步探索Ball Mills Best of 2023 911MetallurgistLaboratory Ball Mills Bench and Floor Jar Mills Gilson Co.

Ball mill Wikipedia

OverviewWorkingApplicationsDescriptionAdvantages of the ball millVarietiesSee also

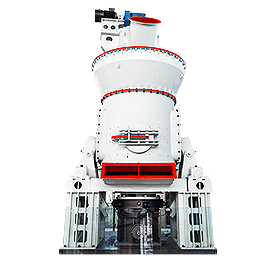

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axi

Wikipedia CC-BY-SA 许可下的文字预计阅读时间:8 分钟

Ball Mill an overview ScienceDirect Topics

The ball mill contains a hollow cylindrical shell that rotates about its axis. This cylinder is filled with balls that are made of stainless steel or rubber to the material contained in it.

Ball milling: a green technology for the preparation and

Ball milling is a simple, fast, cost-effective green technology with enormous potential. One of the most interesting applications of this technology in the field of cellulose is the

Energy efficient cement ball mill from

An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low

Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems

2021年2月26日The choice of a drive system for a ball mill used in copper ore comminution is largely dictated by the energy-related criteria. The energy efficiency of

Ball Mill an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter ( Figure 8.11 ). The feed can be

Full gear unit range for your horizontal mill

Among the different types of horizontal mills used in the mining industry, SAG, AG, rod and ball mills are usually equipped with lateral drives. We offer you a full package of complete drive systems, consisting of girth

Ball Mill- Ball Mill manufacturer, supplier Pelletizing

2023年6月6日Greenfield Tech Projects is well recognized company engaged in the development of turnkey projects and manufacturing finest quality equipments. We are

Ball Mill RETSCH powerful grinding and homogenization

The High Energy Ball Mill Emax and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry.

Ball Mill at Thomas Scientific

High-energy ball mill with dual clamps that accommodates sample sizes ranging from 0.2 10 grams. Ideal for grinding dry, brittle samples, mechanical alloying, slurry grinding, blending powders, and mixing emulsions. Typical samples include rocks, minerals, sand, cement, slag, ceramics, catalyst. Compare this item.

行星式球磨仪PM100--德国RETSCH(莱驰)研磨仪粉碎仪

Download. The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml

Ball milling: a green technology for the preparation and

Ball milling is a simple, fast, cost-effective green technology with enormous potential. One of the most interesting applications of this technology in the field of cellulose is the preparation and the chemical modification of cellulose nanocrystals and nanofibers.

Energy Efficiency Analysis of Copper Ore Ball Mill Drive

2021年2月26日Analysis of Variant Ball Mill Drive Systems. The basic element of a ball mill is the drum, in which the milling process takes place ( Figure 1 ). The length of the drum in the analyzed mill (without the lining) is 3.6 m, and the internal diameter is 3.4 m. The mass of the drum without the grinding media is 84 Mg.

The operating principle of the ball mill

2017年2月8日Mill productivity also depends on other factors: number of the drum rotations, the grinding fineness, humidity and size of the crushed material, timely removal the finished product. Ball mills characterized by

Ball Mill [PDF Document]

2014年11月13日Ball mill is generally used to grind material 1/4 inch and finer, down to the particle. size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must. be operated in a closed system. There is a specific operating speed for

Energy efficient cement ball mill from

Key benefits. High reliability over a century of experience with 4000+ ball mills installed globally. Large through-flow area ensures low pressure drop across the mill. Horizontal slide shoe bearing design allows much

Planetary ball mill XQM series EnviSense

XQM series planetary ball mill has four ball grinding tanks installed on one turnplate. The product can smash and blend various products of different materials and granularity with dry or wet methods. Minimum granularity

Ball Mills 911 Metallurgist

2017年2月13日Ball Mills Ball Mills In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod

Ball Mill RETSCH powerful grinding and homogenization

The High Energy Ball Mill Emax and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry.

Ball Mill at Thomas Scientific

High-energy ball mill with dual clamps that accommodates sample sizes ranging from 0.2 10 grams. Ideal for grinding dry, brittle samples, mechanical alloying, slurry grinding, blending powders, and mixing emulsions. Typical samples include rocks, minerals, sand, cement, slag, ceramics, catalyst. Compare this item.

行星式球磨仪PM100--德国RETSCH(莱驰)研磨仪粉碎仪

Download. The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml

Energy efficient cement ball mill from

Key benefits. High reliability over a century of experience with 4000+ ball mills installed globally. Large through-flow area ensures low pressure drop across the mill. Horizontal slide shoe bearing design allows much

Energy Efficiency Analysis of Copper Ore Ball Mill Drive

2021年2月26日Analysis of Variant Ball Mill Drive Systems. The basic element of a ball mill is the drum, in which the milling process takes place ( Figure 1 ). The length of the drum in the analyzed mill (without the lining) is 3.6 m, and the internal diameter is 3.4 m. The mass of the drum without the grinding media is 84 Mg.

The operating principle of the ball mill

2017年2月8日Mill productivity also depends on other factors: number of the drum rotations, the grinding fineness, humidity and size of the crushed material, timely removal the finished product. Ball mills characterized by

Ball Mill [PDF Document]

2014年11月13日Ball mill is generally used to grind material 1/4 inch and finer, down to the particle. size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must. be operated in a closed system. There is a specific operating speed for

Planetary ball mill XQM series EnviSense

1 Nasza oferta Planetary ball mill XQM series font size Print Email Planetary ball mill XQM series are the requisite equipment for mixing, fine grinding, small sample preparing, new product development and small

KFD-Series Full-Directional Planetary Ball Mill 한국코프로텍(주)

KFD-Series Full-Directional Planetary Ball Mill. Overview. KFD series planetary ball mill has four ball grinding tanks installed on one disc. When the turn disc rotates, the mill pots revolve on their own axis and make 360 degree rotation. And the balls in the tanks grind and mix samples in high speed movement.

Ball Mill at Thomas Scientific

High-energy ball mill with dual clamps that accommodates sample sizes ranging from 0.2 10 grams. Ideal for grinding dry, brittle samples, mechanical alloying, slurry grinding,

Ball mill Wikipedia

OverviewWorkingApplicationsDescriptionAdvantages of the ball millVarietiesSee also

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axi

Ball Mill an overview ScienceDirect Topics

The ball mill contains a hollow cylindrical shell that rotates about its axis. This cylinder is filled with balls that are made of stainless steel or rubber to the material contained in it.

Ball milling: a green technology for the preparation and

Ball milling is a simple, fast, cost-effective green technology with enormous potential. One of the most interesting applications of this technology in the field of cellulose is the

Energy efficient cement ball mill from

An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low

Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems

2021年2月26日The choice of a drive system for a ball mill used in copper ore comminution is largely dictated by the energy-related criteria. The energy efficiency of

Ball Mill an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter ( Figure 8.11 ). The feed can be

Full gear unit range for your horizontal mill

Among the different types of horizontal mills used in the mining industry, SAG, AG, rod and ball mills are usually equipped with lateral drives. We offer you a full package of complete drive systems, consisting of girth

Ball Mill- Ball Mill manufacturer, supplier Pelletizing

2023年6月6日Greenfield Tech Projects is well recognized company engaged in the development of turnkey projects and manufacturing finest quality equipments. We are

Ball Mill RETSCH powerful grinding and homogenization

The High Energy Ball Mill Emax and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry.

Ball Mill at Thomas Scientific

High-energy ball mill with dual clamps that accommodates sample sizes ranging from 0.2 10 grams. Ideal for grinding dry, brittle samples, mechanical alloying, slurry grinding, blending powders, and mixing emulsions. Typical samples include rocks, minerals, sand, cement, slag, ceramics, catalyst. Compare this item.

行星式球磨仪PM100--德国RETSCH(莱驰)研磨仪粉碎仪

Download. The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml

Ball milling: a green technology for the preparation and

Ball milling is a simple, fast, cost-effective green technology with enormous potential. One of the most interesting applications of this technology in the field of cellulose is the preparation and the chemical modification of cellulose nanocrystals and nanofibers.

Energy Efficiency Analysis of Copper Ore Ball Mill Drive

2021年2月26日Analysis of Variant Ball Mill Drive Systems. The basic element of a ball mill is the drum, in which the milling process takes place ( Figure 1 ). The length of the drum in the analyzed mill (without the lining) is 3.6 m, and the internal diameter is 3.4 m. The mass of the drum without the grinding media is 84 Mg.

The operating principle of the ball mill

2017年2月8日Mill productivity also depends on other factors: number of the drum rotations, the grinding fineness, humidity and size of the crushed material, timely removal the finished product. Ball mills characterized by

Ball Mill [PDF Document]

2014年11月13日Ball mill is generally used to grind material 1/4 inch and finer, down to the particle. size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must. be operated in a closed system. There is a specific operating speed for

Energy efficient cement ball mill from

Key benefits. High reliability over a century of experience with 4000+ ball mills installed globally. Large through-flow area ensures low pressure drop across the mill. Horizontal slide shoe bearing design allows much

Planetary ball mill XQM series EnviSense

XQM series planetary ball mill has four ball grinding tanks installed on one turnplate. The product can smash and blend various products of different materials and granularity with dry or wet methods. Minimum granularity

Ball Mills 911 Metallurgist

2017年2月13日Ball Mills Ball Mills In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod

Ball Mill RETSCH powerful grinding and homogenization

The High Energy Ball Mill Emax and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry.

Ball Mill at Thomas Scientific

High-energy ball mill with dual clamps that accommodates sample sizes ranging from 0.2 10 grams. Ideal for grinding dry, brittle samples, mechanical alloying, slurry grinding, blending powders, and mixing emulsions. Typical samples include rocks, minerals, sand, cement, slag, ceramics, catalyst. Compare this item.

行星式球磨仪PM100--德国RETSCH(莱驰)研磨仪粉碎仪

Download. The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml

Energy efficient cement ball mill from

Key benefits. High reliability over a century of experience with 4000+ ball mills installed globally. Large through-flow area ensures low pressure drop across the mill. Horizontal slide shoe bearing design allows much

Energy Efficiency Analysis of Copper Ore Ball Mill Drive

2021年2月26日Analysis of Variant Ball Mill Drive Systems. The basic element of a ball mill is the drum, in which the milling process takes place ( Figure 1 ). The length of the drum in the analyzed mill (without the lining) is 3.6 m, and the internal diameter is 3.4 m. The mass of the drum without the grinding media is 84 Mg.

The operating principle of the ball mill

2017年2月8日Mill productivity also depends on other factors: number of the drum rotations, the grinding fineness, humidity and size of the crushed material, timely removal the finished product. Ball mills characterized by

Ball Mill [PDF Document]

2014年11月13日Ball mill is generally used to grind material 1/4 inch and finer, down to the particle. size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must. be operated in a closed system. There is a specific operating speed for

Planetary ball mill XQM series EnviSense

1 Nasza oferta Planetary ball mill XQM series font size Print Email Planetary ball mill XQM series are the requisite equipment for mixing, fine grinding, small sample preparing, new product development and small

KFD-Series Full-Directional Planetary Ball Mill 한국코프로텍(주)

KFD-Series Full-Directional Planetary Ball Mill. Overview. KFD series planetary ball mill has four ball grinding tanks installed on one disc. When the turn disc rotates, the mill pots revolve on their own axis and make 360 degree rotation. And the balls in the tanks grind and mix samples in high speed movement.

كسارة محمولة mesin pemecah batu للبيع

المعلومات التقنية

محطم الدوار رمح المواد

minerio de ferro ao ao linha que faz a maquina de processamento

القوة الكهربائية مطحنة صغيرة بريثي

بعض 0ne غول 2 مطحنة الساخنة

صغيرة طاحونة الفحم حجم aagarbatti

معدات كسارة الحجارة في ألمانيا

سنگ شکن در شرق دور برای فروش استفاده می شود

كسارة مخروطية التحكم في الدائرة

الطفرة كسارة فرش التوأم

آلة طحن مع جنيه المغناطيسي

بيع هوهونغ عالية المواصفات مطحنة الكرة سحق المواد

الكمبيوتر الكسارات كيف تسير الامور الرقم

معدات سحق التعدين في زامبيا

stone crusher machine pakistan

خرج من المعدات الميكانيكية الشوائب

طحن طحن الملاط

صنع هزاز المغناطيسي

كسارة مخروطية شركة بويبلو

إثيوبيا تصنيع خط تجهيز خام الحديد للبيع

خام الحديد سحق تشغيل المعدات

ابزارهای ساخته شده از شن و ماسه

مطحنة ريمون بطاقة 8 طن في الساعة وما فوق المصنعين في الهند

مصنعي معدات معالجة المعادن كندا

باكستان الرخام صور آلة

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20