الحار منتجات

ملكنا الإخبارية

jamming in iron ore crushing plant

Comminution and classification technologies of iron ore

2022年1月1日Hematite and magnetite iron ores are the most prominent raw materials for iron and steel production. Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications

Crushing Plant an overview ScienceDirect Topics

7.1 A crushing plant delivered ore to a wet grinding mill for further size reduction. The size of crushed ore (F80) was. 4.0 mm and the S.G. 2.8 t/m 3. The work index of the ore was

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A

进一步探索Iron Ore Processing Flowsheet Multotec(PDF) iron-steel making From start to finish ResearchGate

Ore Treatment an overview ScienceDirect Topics

It can treat weakly magnetic minerals in the size range 0–2.0 mm and has been used in industry for upgrading roasted kaolin of 0–0.2 mm by removing the impurities of oxidized

Iron Ore production in the Pilbara

Exploration and evaluation The team identifies and quantifies ore bodies, by using a range of geological, geophysical and metallurgical techniques. In its simplest form exploration

(PDF) Research into the crushing and grinding

2019年1月1日Main properties of the processes of iron ore destruction in terms of its simultaneous effect by mechanical load and electric field of ultra-high frequency have been studied.

Crushing Plant Design and Layout Considerations 911

Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC MiningMetals,Vancouver, BC ABSTRACT In mining operations, the layout of

Crushing and Grinding WetSticky Ore 911 Metallurgist

2016年5月9日In the handling of wet, sticky ores such as encountered in tropical areas having distinct dry and rainy seasons, the crushing plant is a section of the mill which must be planned very carefully. Unless this is

OPTIMIZATION OF MINERAL PROCESSING PLANT THROUGH

A mining operation of an iron ore mine is shown in Figure 1, with visible mining equipment and facility. Fig. 1. A mining operation of an iron ore mine, including drilling, ROM ore,

/sbm jamming in iron ore crushing plant.md at master

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

Failure Analysis and Improvement Measures of Grate Bars Used in Iron

2021年5月11日Stainless steel grate bars are one of the important components of pallet cars used in straight grate iron ore pelletizing plant. Their service life has a major influence on plant productivity and pellet quality. The objective of this work is to find the root cause of grate bars premature failure and suggest preventive measures. To reach this objective,

Developments in iron ore comminution and classification

2015年1月1日Abstract Hematite and magnetite, the two predominantiron ores, require different processing routes. High-grade hematite direct shipping ores (DSOs) generally only require crushing and screening to meet the size requirements of lump (typically between 6 and 30 mm) and fines (typically less than 6 mm) products.

Crushing Plant an overview ScienceDirect Topics

7.1 A crushing plant delivered ore to a wet grinding mill for further size reduction. The size of crushed ore (F80) was. 4.0 mm and the S.G. 2.8 t/m 3. The work index of the ore was determined as 12.2 kWh/t.

(PDF) SIZE REDUCTION BY CRUSHING METHODS

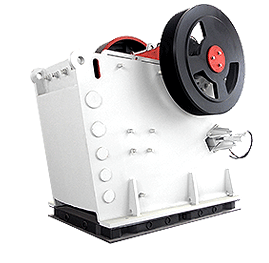

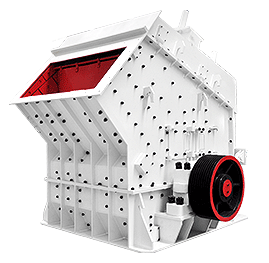

2017年3月4日plants are used for primary crushing of bulk materials mainly in ore mines and in the n atural rock industry. Today, stationary, semi-mobile and m obile crushing plants with capacities ranging from

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Ore Treatment an overview ScienceDirect Topics

Traditional practice was to return the ground material to the rougher; modern practice is to treat it in a secondary circuit more appropriate to the reduced particle size, and also to prevent massive swings in the circulating load through the rougher. In reality, at each stage of separation, not all particles report to their correct outlet stream.

Iron Ore production in the Pilbara

Exploration and evaluation The team identifies and quantifies ore bodies, by using a range of geological, geophysical and metallurgical techniques. In its simplest form exploration involves drilling in remote areas to sample areas. Metallurgicalassessment

Crushing Plant Design and Layout Considerations 911 Metallurgist

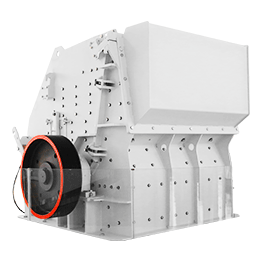

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of parties.

Crushing and Grinding WetSticky Ore 911

2016年5月9日A high pressure water spray over the grizzly often aids in the subsequent jaw crusher operation. The fines from the grizzly and the crusher discharge pass by gravity and/or conveyor to a Combination

Iron Ore, Sample Preparation and Analysis of ResearchGate

2006年9月15日Iron Ore, Sample Preparation and Analysis of Authors: Om P. Bhargava Abstract The iron ore industry is an important segment of the world economy. The main mineral oxides are magnetite and...

Failure Analysis and Improvement Measures of Grate Bars Used in Iron

2021年5月11日Iron ore pelletizing is a process in which powdered iron ore along with a certain amount of fluxing materials (5-10%), binder (0.4-0.8%) and solid carbonaceous fuel (such as anthracite coal or coke breeze) are rolled into the spherical bodies having a diameter of 6-16 mm in size (Ref 1 ).

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日SIZE REDUCTION BY CRUSHING METHODS Authors: A. Balasubramanian University of Mysore In the field of extractive metallurgy, mineral dressing is the process of separating commercially valuable...

Crushing Circuit an overview ScienceDirect Topics

The first step of physical beneficiation is crushing and grinding the iron ore to its liberation size, the maximum size where individual particles of gangue are separated from the iron minerals. A flow sheet of a typical iron ore crushing and grinding circuit is shown in Figure 1.2.2 (based on Ref. [ 4 ]).

Ore Treatment an overview ScienceDirect Topics

Traditional practice was to return the ground material to the rougher; modern practice is to treat it in a secondary circuit more appropriate to the reduced particle size, and also to prevent massive swings in the circulating load through the rougher. In reality, at each stage of separation, not all particles report to their correct outlet stream.

The six main steps of iron ore processing Multotec

Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

11.23 Taconite Ore Processing

of the processed ore shipped to the iron and steel industry is in the form of pellets. Other forms of processed ore include sinter and briquettes. The average iron content of pellets is 63 percent. 11.23.2 Process Description2-5,41 Processing of taconite consists of crushing and grinding the ore to liberate iron-bearing particles,

Crushing and Grinding WetSticky Ore 911

2016年5月9日A high pressure water spray over the grizzly often aids in the subsequent jaw crusher operation. The fines from the grizzly and the crusher discharge pass by gravity and/or conveyor to a Combination

Iron Ore, Sample Preparation and Analysis of ResearchGate

2006年9月15日Iron Ore, Sample Preparation and Analysis of Authors: Om P. Bhargava Abstract The iron ore industry is an important segment of the world economy. The main mineral oxides are magnetite and...

Iron processing Ores, Surface Mining, Sintering, and Pelletizing

Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine. The most widely distributed iron-bearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is red;

Ore Treatment an overview ScienceDirect Topics

It can treat weakly magnetic minerals in the size range 0–2.0 mm and has been used in industry for upgrading roasted kaolin of 0–0.2 mm by removing the impurities of oxidized

Iron Ore production in the Pilbara

Exploration and evaluation The team identifies and quantifies ore bodies, by using a range of geological, geophysical and metallurgical techniques. In its simplest form exploration

(PDF) Research into the crushing and grinding

2019年1月1日Main properties of the processes of iron ore destruction in terms of its simultaneous effect by mechanical load and electric field of ultra-high frequency have been studied.

Crushing Plant Design and Layout Considerations 911

Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC MiningMetals,Vancouver, BC ABSTRACT In mining operations, the layout of

Crushing and Grinding WetSticky Ore 911 Metallurgist

2016年5月9日In the handling of wet, sticky ores such as encountered in tropical areas having distinct dry and rainy seasons, the crushing plant is a section of the mill which must be planned very carefully. Unless this is

OPTIMIZATION OF MINERAL PROCESSING PLANT THROUGH

A mining operation of an iron ore mine is shown in Figure 1, with visible mining equipment and facility. Fig. 1. A mining operation of an iron ore mine, including drilling, ROM ore,

/sbm jamming in iron ore crushing plant.md at master

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

Failure Analysis and Improvement Measures of Grate Bars Used in Iron

2021年5月11日Stainless steel grate bars are one of the important components of pallet cars used in straight grate iron ore pelletizing plant. Their service life has a major influence on plant productivity and pellet quality. The objective of this work is to find the root cause of grate bars premature failure and suggest preventive measures. To reach this objective,

Developments in iron ore comminution and classification

2015年1月1日Abstract Hematite and magnetite, the two predominantiron ores, require different processing routes. High-grade hematite direct shipping ores (DSOs) generally only require crushing and screening to meet the size requirements of lump (typically between 6 and 30 mm) and fines (typically less than 6 mm) products.

Crushing Plant an overview ScienceDirect Topics

7.1 A crushing plant delivered ore to a wet grinding mill for further size reduction. The size of crushed ore (F80) was. 4.0 mm and the S.G. 2.8 t/m 3. The work index of the ore was determined as 12.2 kWh/t.

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日plants are used for primary crushing of bulk materials mainly in ore mines and in the n atural rock industry. Today, stationary, semi-mobile and m obile crushing plants with capacities ranging from

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Ore Treatment an overview ScienceDirect Topics

Traditional practice was to return the ground material to the rougher; modern practice is to treat it in a secondary circuit more appropriate to the reduced particle size, and also to prevent massive swings in the circulating load through the rougher. In reality, at each stage of separation, not all particles report to their correct outlet stream.

Iron Ore production in the Pilbara

Exploration and evaluation The team identifies and quantifies ore bodies, by using a range of geological, geophysical and metallurgical techniques. In its simplest form exploration involves drilling in remote areas to sample areas. Metallurgicalassessment

Crushing Plant Design and Layout Considerations 911 Metallurgist

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of parties.

Crushing and Grinding WetSticky Ore 911

2016年5月9日A high pressure water spray over the grizzly often aids in the subsequent jaw crusher operation. The fines from the grizzly and the crusher discharge pass by gravity and/or conveyor to a Combination

Iron Ore, Sample Preparation and Analysis of ResearchGate

2006年9月15日Iron Ore, Sample Preparation and Analysis of Authors: Om P. Bhargava Abstract The iron ore industry is an important segment of the world economy. The main mineral oxides are magnetite and...

Failure Analysis and Improvement Measures of Grate Bars Used in Iron

2021年5月11日Iron ore pelletizing is a process in which powdered iron ore along with a certain amount of fluxing materials (5-10%), binder (0.4-0.8%) and solid carbonaceous fuel (such as anthracite coal or coke breeze) are rolled into the spherical bodies having a diameter of 6-16 mm in size (Ref 1 ).

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日SIZE REDUCTION BY CRUSHING METHODS Authors: A. Balasubramanian University of Mysore In the field of extractive metallurgy, mineral dressing is the process of separating commercially valuable...

Crushing Circuit an overview ScienceDirect Topics

The first step of physical beneficiation is crushing and grinding the iron ore to its liberation size, the maximum size where individual particles of gangue are separated from the iron minerals. A flow sheet of a typical iron ore crushing and grinding circuit is shown in Figure 1.2.2 (based on Ref. [ 4 ]).

Ore Treatment an overview ScienceDirect Topics

Traditional practice was to return the ground material to the rougher; modern practice is to treat it in a secondary circuit more appropriate to the reduced particle size, and also to prevent massive swings in the circulating load through the rougher. In reality, at each stage of separation, not all particles report to their correct outlet stream.

The six main steps of iron ore processing Multotec

Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

11.23 Taconite Ore Processing

of the processed ore shipped to the iron and steel industry is in the form of pellets. Other forms of processed ore include sinter and briquettes. The average iron content of pellets is 63 percent. 11.23.2 Process Description2-5,41 Processing of taconite consists of crushing and grinding the ore to liberate iron-bearing particles,

Crushing and Grinding WetSticky Ore 911

2016年5月9日A high pressure water spray over the grizzly often aids in the subsequent jaw crusher operation. The fines from the grizzly and the crusher discharge pass by gravity and/or conveyor to a Combination

Iron Ore, Sample Preparation and Analysis of ResearchGate

2006年9月15日Iron Ore, Sample Preparation and Analysis of Authors: Om P. Bhargava Abstract The iron ore industry is an important segment of the world economy. The main mineral oxides are magnetite and...

Iron processing Ores, Surface Mining, Sintering, and Pelletizing

Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine. The most widely distributed iron-bearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is red;

الديزل المتنقلة وحدة محطم

قطعات سنگ شکن سیمان

الصناعية عالية الكفاءة الصانع تأثير محطم الجرانيت من الصين

توپ فولادی آسیاب با قطر روی از mm به میلی متر

مُصنع آلات تكسير الحجارة

الخبث من صناعة المسابك

الأساس الخرساني في منطقة المحجر

معدات تاجير لوازم البناء

كسارات الممولين في اندونيسيا

تعدين الذهب الجديدة نيوزيلندا فحص الجهاز

التوضيح آلة التكسير

سيور ناقلة المصنعين في السعودية

التقطيع المكثف محطة المحمول للبيع

العمانية محطم الصخور المدرعات

مصنع سحق مصغرة من المورد محطم

الطين الطوب صنع آلة في المملكة المتحدة

مصانع معالجة الأسماك في الصين شنغهاي

خام الرصاص المصنعة كسارة متنقلة الأولية

أودايبور الرخام المعالج

مصنع سحق خام الحديد العماني

الذهب المصنع طرق الطحن في أستراليا

قطع غيار مستعملة للأرز 2540 كسارة الفك رابيدز

معدات الفرن الدوار مستعملة للبيع

Coal mine 80 belt

STUNER كسارة DXN MADE IN

تكلفة مصنع crusherr الحجر

حول لدينا

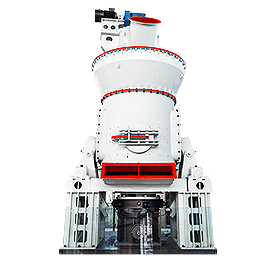

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20