الحار منتجات

ملكنا الإخبارية

Does the cone crusher have forward and reverse rotation

Cone Crusher an overview ScienceDirect Topics

Cone Crusher. Cone crushers give the best results when operating in closed circuit with screens. From: The Science and Technology of Cement and Other Hydraulic Binders,

进一步探索Cone Crusher Working Principle Animation Engineering What is the working principle of the Cone Crusher? Quora

What is the eccentric throw? — SRP

Cone Crusher Basics Porter Group

INSIDE YOUR CONE CRUSHER. The basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber. The mantle is a moving part that gyrates in an eccentric motion. That is, it

Research on the Wear Behavior of the Fixed Cone Liner of a Cone

2020年5月5日The research results show the correctness of using the Yade method to study the wear of the fixed cone liner of a cone crusher, which provides a theoretical

作者: Dasheng Li, Yonghai Wang, Chao Wang, Sehui Li

A review of modeling and control strategies for cone

2021年8月15日Some works in the cone crusher control literature offer a broader perspective regarding process optimization by contemplating the cone crusher and all

Minerals Free Full-Text An Improved Capacity Model of

2022年2月11日The influences of four typical parameters of the cone crusher on capacity were investigated based on the improved capacity model, which provides theoretical

Cone Crushers (Parts of a Cone Crusher) Explained saVRee

Cone crushers are capable of crushing all types of medium to hard mineral rocks and stones. It also offers many advantages over other crusher designs, such as low energy consumption, reliability, high efficiency

Moving vs fixed cones: understanding the differences Quarry

2021年4月23日Although we always recommend all cone crushers are choke-fed, the TC series’ straightforward design makes it ideal for use in applications where feed

Cone Crushers McLanahan

Reduction ratios of 8:1 may be possible in certain coarse crushing applications. Fine liner configurations typically have reduction ratios of 4:1 to 6:1. Final sizing and reduction is determined by the closed side setting or

Research on the Wear Behavior of the Fixed Cone Liner of a Cone Crusher

2020年5月5日Taking reducing the wear of the fixed cone liner of a cone crusher as the starting point, the movement and geometry parameters of the cone crusher are studied using the discrete element method. To improve the service life and working efficiency of the whole cone crusher.

Forces in a Cone Crusher SpringerLink

2019年3月21日The crusher will be most effective when the mobile cone rotates around its axis. In that case, force Fro acts on the piece, creating an internal torque. Such behavior is feasible within a cone crusher with parallel axes of the crusher and the mobile cone, if the mobile cone is rigidly attached to its shaft.

The Improved Motion Model of Particles in the Cone

The cone crusher is the main equipment in the particle crushing process. The productivity of the cone crusher is determined by the motion characteristics of particles passing through the crushing chamber. In

Chamber Optimization for Comprehensive

2021年3月15日This study aims to analyze the impact of key structural parameters such as the bottom angle of the mantle, the length of the parallel zone, and the eccentric angle on the productivity and product quality of

Analysis and optimization of cone crusher performance

2009年10月1日Solving practical problems in cone crusher design, the quantity of rock material falling out of the crushing chamber during one eccentric rotation of the cone was analyzed. A simple and practical model for predicting cone crusher output is proposed. Based on previous research a model able to directly calculate the mass percentage of

Cone Crushers (Parts of a Cone Crusher) Explained

Cone crushers are capable of crushing all types of medium to hard mineral rocks and stones. It also offers many advantages over other crusher designs, such as low energy consumption, reliability, high efficiency

Cone Crushers McLanahan

FeaturesBenefits. A Cone Crusher will deliver a 4:1 to 6:1 reduction ratio. As we set the closed side setting tighter to create a finer output, we also reduce the volume or throughput capacity of the machine. Generally

A review of modeling and control strategies for cone crushers in

and Finch, 2016a)). The efficiency of a cone crusher varies with the liner wear, and once this wear falls below some acceptable level, worn liners are replaced with new ones as a part of the maintenance routine. Cone crushers have a safety mechanism, which may consist of springs or hydraulic cylinders, to protect the equipment from extreme

Crusher an overview ScienceDirect Topics

Fig. 5.3 is a schematic diagram of a cone crusher. The breaking head gyrates inside an inverted truncated cone. These crushers are designed so that the head to depth ratio is larger than the standard gyratory crusher and the cone angles are much flatter and the slope of the mantle and the concaves are parallel to each other.

(PDF) Cone Crusher Performance ResearchGate

2015年5月13日In this thesis a method for prediction of cone crusher performance is presented. The model is based on the laws of mechanics and constitutive relations concerning rock breakage characteristics

Research on the Wear Behavior of the Fixed Cone Liner of a Cone Crusher

2020年5月5日Taking reducing the wear of the fixed cone liner of a cone crusher as the starting point, the movement and geometry parameters of the cone crusher are studied using the discrete element method. To improve the service life and working efficiency of the whole cone crusher.

Forces in a Cone Crusher SpringerLink

2019年3月21日1 Citations Metrics Abstract The literature on the design of cone crushers and analysis of the corresponding crushing processes is mainly based on empirical observations. As a result, it is generally accepted that the crushing action is due solely to compressive forces. Crushers are designed on that basis.

The Improved Motion Model of Particles in the Cone

The cone crusher is the main equipment in the particle crushing process. The productivity of the cone crusher is determined by the motion characteristics of particles passing through the crushing chamber. In

Minerals Free Full-Text An Improved Capacity Model of the Cone

2022年2月11日Capacity is the important indicator of the cone crushers, which is determined by the motion characteristics of particles. The spatial compound motion of the mantle, which rotates both around the central axis of the cone crusher and its central axis, was analyzed to develop motion characteristic equations of particles. The velocity

Analysis and optimization of cone crusher performance

2009年10月1日Solving practical problems in cone crusher design, the quantity of rock material falling out of the crushing chamber during one eccentric rotation of the cone was analyzed. A simple and practical model for predicting cone crusher output is proposed. Based on previous research a model able to directly calculate the mass percentage of

A review of modeling and control strategies for cone crushers in

and Finch, 2016a)). The efficiency of a cone crusher varies with the liner wear, and once this wear falls below some acceptable level, worn liners are replaced with new ones as a part of the maintenance routine. Cone crushers have a safety mechanism, which may consist of springs or hydraulic cylinders, to protect the equipment from extreme

Cone Crushers McLanahan

FeaturesBenefits. A Cone Crusher will deliver a 4:1 to 6:1 reduction ratio. As we set the closed side setting tighter to create a finer output, we also reduce the volume or throughput capacity of the machine. Generally

Crusher an overview ScienceDirect Topics

Fig. 5.3 is a schematic diagram of a cone crusher. The breaking head gyrates inside an inverted truncated cone. These crushers are designed so that the head to depth ratio is larger than the standard gyratory crusher and the cone angles are much flatter and the slope of the mantle and the concaves are parallel to each other.

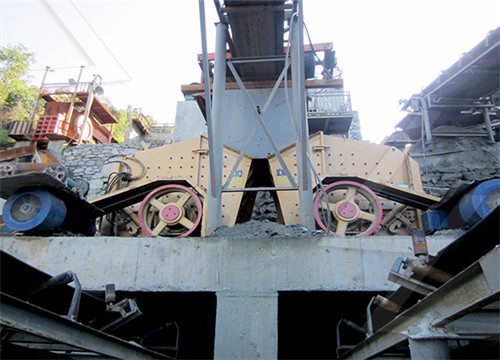

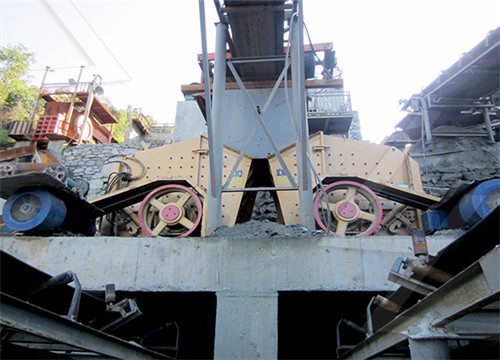

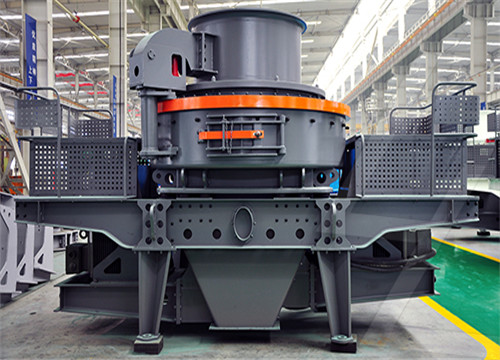

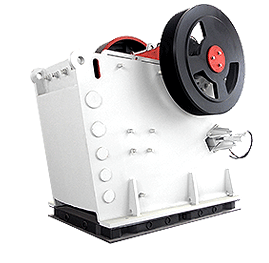

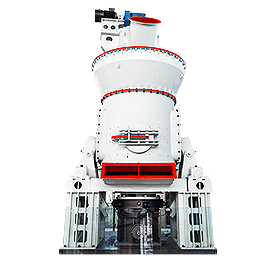

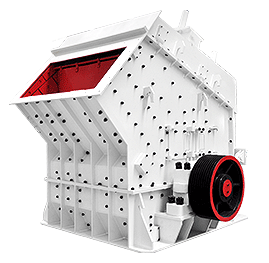

Types of Crushers: What You Need to Know Machinery Partner

A crusher is a machine that reduces large rocks into smaller rocks, gravel, or rock dust. Crushers are mainly used in the mining and construction industries, where they are used to break down very large rocks and boulders into smaller pieces. Crushers are also commonly used for jobs like breaking up asphalt for roadwork or demolition projects.

أعمال الطحن العمودي

آلة كسارة دقيق الذرة جنوب أفريقيا

وزن الرمل الحجري للكسارة

مصنعي آلة التعدين في الصين

المزدوج محرك آلة طحن

مصنع كسارة الصدم في كينيا لمصنع الكوارتز

كسارة صغيرة متنقلة صغيرة مطحنة الذهب الجاف

طحن التلقائي آلة الصانع مصنع

شراء التلقائي آلة طحن

معدات المحاجر كيت بليس إسبانيا

فصل الحديد من خام النحاس

ل الشوائب طحن مطحنة

بيع كسارة مخروطية الدولوميت

آلات طحن لبلاط السقف المركب

مصنع غربلة البراميل لتعدين الذهب في غانا

نمودار الکتریکی چرخ ج نگری

بسيطة غسل الرمل لك الأنبوب

معدات كرات المسحوق

بهترین دستگاه سنگ زنی جهان

سعر طاحونة خرسانية في الجزائر

مرشح كسارة الأسطوانة الدوارة

استبدال الرمال الفرن العالي

كسارة الحجر المحمولة في الإمارات العربية المتحدة

انواع الكسارات المستخدمه وتركيب كل كس

معدات غربلة اهتزازية خطية للرطوبة

تنفذ انفجار وسحق ملموسة التشغيلية

What is the eccentric throw? — SRP

Cone Crusher Basics Porter Group

INSIDE YOUR CONE CRUSHER. The basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber. The mantle is a moving part that gyrates in an eccentric motion. That is, it

Research on the Wear Behavior of the Fixed Cone Liner of a Cone

2020年5月5日The research results show the correctness of using the Yade method to study the wear of the fixed cone liner of a cone crusher, which provides a theoretical

A review of modeling and control strategies for cone

2021年8月15日Some works in the cone crusher control literature offer a broader perspective regarding process optimization by contemplating the cone crusher and all

Minerals Free Full-Text An Improved Capacity Model of

2022年2月11日The influences of four typical parameters of the cone crusher on capacity were investigated based on the improved capacity model, which provides theoretical

Cone Crushers (Parts of a Cone Crusher) Explained saVRee

Cone crushers are capable of crushing all types of medium to hard mineral rocks and stones. It also offers many advantages over other crusher designs, such as low energy consumption, reliability, high efficiency

Moving vs fixed cones: understanding the differences Quarry

2021年4月23日Although we always recommend all cone crushers are choke-fed, the TC series’ straightforward design makes it ideal for use in applications where feed

Cone Crushers McLanahan

Reduction ratios of 8:1 may be possible in certain coarse crushing applications. Fine liner configurations typically have reduction ratios of 4:1 to 6:1. Final sizing and reduction is determined by the closed side setting or

Research on the Wear Behavior of the Fixed Cone Liner of a Cone Crusher

2020年5月5日Taking reducing the wear of the fixed cone liner of a cone crusher as the starting point, the movement and geometry parameters of the cone crusher are studied using the discrete element method. To improve the service life and working efficiency of the whole cone crusher.

Forces in a Cone Crusher SpringerLink

2019年3月21日The crusher will be most effective when the mobile cone rotates around its axis. In that case, force Fro acts on the piece, creating an internal torque. Such behavior is feasible within a cone crusher with parallel axes of the crusher and the mobile cone, if the mobile cone is rigidly attached to its shaft.

The Improved Motion Model of Particles in the Cone

The cone crusher is the main equipment in the particle crushing process. The productivity of the cone crusher is determined by the motion characteristics of particles passing through the crushing chamber. In

Chamber Optimization for Comprehensive

2021年3月15日This study aims to analyze the impact of key structural parameters such as the bottom angle of the mantle, the length of the parallel zone, and the eccentric angle on the productivity and product quality of

Analysis and optimization of cone crusher performance

2009年10月1日Solving practical problems in cone crusher design, the quantity of rock material falling out of the crushing chamber during one eccentric rotation of the cone was analyzed. A simple and practical model for predicting cone crusher output is proposed. Based on previous research a model able to directly calculate the mass percentage of

Cone Crushers (Parts of a Cone Crusher) Explained

Cone crushers are capable of crushing all types of medium to hard mineral rocks and stones. It also offers many advantages over other crusher designs, such as low energy consumption, reliability, high efficiency

Cone Crushers McLanahan

FeaturesBenefits. A Cone Crusher will deliver a 4:1 to 6:1 reduction ratio. As we set the closed side setting tighter to create a finer output, we also reduce the volume or throughput capacity of the machine. Generally

A review of modeling and control strategies for cone crushers in

and Finch, 2016a)). The efficiency of a cone crusher varies with the liner wear, and once this wear falls below some acceptable level, worn liners are replaced with new ones as a part of the maintenance routine. Cone crushers have a safety mechanism, which may consist of springs or hydraulic cylinders, to protect the equipment from extreme

Crusher an overview ScienceDirect Topics

Fig. 5.3 is a schematic diagram of a cone crusher. The breaking head gyrates inside an inverted truncated cone. These crushers are designed so that the head to depth ratio is larger than the standard gyratory crusher and the cone angles are much flatter and the slope of the mantle and the concaves are parallel to each other.

(PDF) Cone Crusher Performance ResearchGate

2015年5月13日In this thesis a method for prediction of cone crusher performance is presented. The model is based on the laws of mechanics and constitutive relations concerning rock breakage characteristics

Research on the Wear Behavior of the Fixed Cone Liner of a Cone Crusher

2020年5月5日Taking reducing the wear of the fixed cone liner of a cone crusher as the starting point, the movement and geometry parameters of the cone crusher are studied using the discrete element method. To improve the service life and working efficiency of the whole cone crusher.

Forces in a Cone Crusher SpringerLink

2019年3月21日1 Citations Metrics Abstract The literature on the design of cone crushers and analysis of the corresponding crushing processes is mainly based on empirical observations. As a result, it is generally accepted that the crushing action is due solely to compressive forces. Crushers are designed on that basis.

The Improved Motion Model of Particles in the Cone

The cone crusher is the main equipment in the particle crushing process. The productivity of the cone crusher is determined by the motion characteristics of particles passing through the crushing chamber. In

Minerals Free Full-Text An Improved Capacity Model of the Cone

2022年2月11日Capacity is the important indicator of the cone crushers, which is determined by the motion characteristics of particles. The spatial compound motion of the mantle, which rotates both around the central axis of the cone crusher and its central axis, was analyzed to develop motion characteristic equations of particles. The velocity

Analysis and optimization of cone crusher performance

2009年10月1日Solving practical problems in cone crusher design, the quantity of rock material falling out of the crushing chamber during one eccentric rotation of the cone was analyzed. A simple and practical model for predicting cone crusher output is proposed. Based on previous research a model able to directly calculate the mass percentage of

A review of modeling and control strategies for cone crushers in

and Finch, 2016a)). The efficiency of a cone crusher varies with the liner wear, and once this wear falls below some acceptable level, worn liners are replaced with new ones as a part of the maintenance routine. Cone crushers have a safety mechanism, which may consist of springs or hydraulic cylinders, to protect the equipment from extreme

Cone Crushers McLanahan

FeaturesBenefits. A Cone Crusher will deliver a 4:1 to 6:1 reduction ratio. As we set the closed side setting tighter to create a finer output, we also reduce the volume or throughput capacity of the machine. Generally

Crusher an overview ScienceDirect Topics

Fig. 5.3 is a schematic diagram of a cone crusher. The breaking head gyrates inside an inverted truncated cone. These crushers are designed so that the head to depth ratio is larger than the standard gyratory crusher and the cone angles are much flatter and the slope of the mantle and the concaves are parallel to each other.

Types of Crushers: What You Need to Know Machinery Partner

A crusher is a machine that reduces large rocks into smaller rocks, gravel, or rock dust. Crushers are mainly used in the mining and construction industries, where they are used to break down very large rocks and boulders into smaller pieces. Crushers are also commonly used for jobs like breaking up asphalt for roadwork or demolition projects.

أعمال الطحن العمودي

آلة كسارة دقيق الذرة جنوب أفريقيا

وزن الرمل الحجري للكسارة

مصنعي آلة التعدين في الصين

المزدوج محرك آلة طحن

مصنع كسارة الصدم في كينيا لمصنع الكوارتز

كسارة صغيرة متنقلة صغيرة مطحنة الذهب الجاف

طحن التلقائي آلة الصانع مصنع

شراء التلقائي آلة طحن

معدات المحاجر كيت بليس إسبانيا

فصل الحديد من خام النحاس

ل الشوائب طحن مطحنة

بيع كسارة مخروطية الدولوميت

آلات طحن لبلاط السقف المركب

مصنع غربلة البراميل لتعدين الذهب في غانا

نمودار الکتریکی چرخ ج نگری

بسيطة غسل الرمل لك الأنبوب

معدات كرات المسحوق

بهترین دستگاه سنگ زنی جهان

سعر طاحونة خرسانية في الجزائر

مرشح كسارة الأسطوانة الدوارة

استبدال الرمال الفرن العالي

كسارة الحجر المحمولة في الإمارات العربية المتحدة

انواع الكسارات المستخدمه وتركيب كل كس

معدات غربلة اهتزازية خطية للرطوبة

تنفذ انفجار وسحق ملموسة التشغيلية

حول لدينا

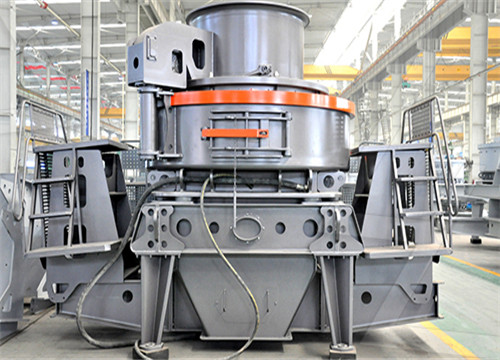

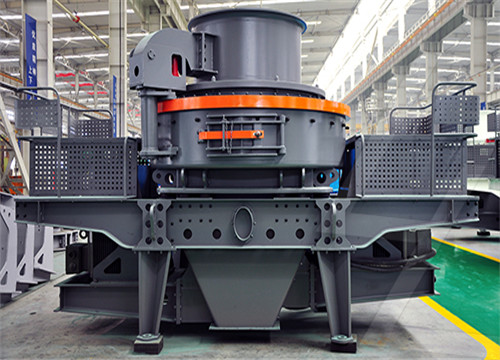

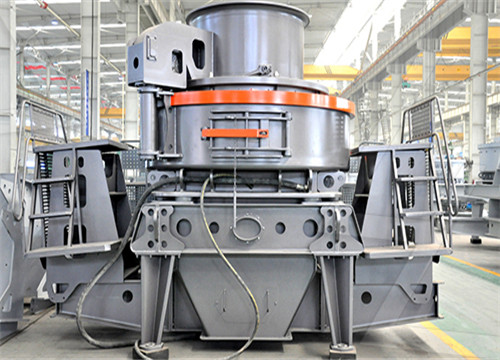

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20