الحار منتجات

ملكنا الإخبارية

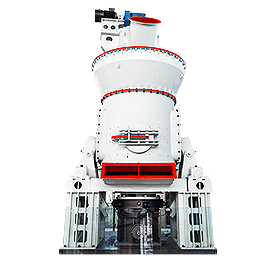

ball mill for both

Ball Mill an overview ScienceDirect Topics

Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on small and large scales. Grinding elements in ball mills

Ball Mill RETSCH powerful grinding and homogenization

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and

进一步探索Ball Mills The Laboratory StoreLab Ball Mills

Ball mill Wikipedia

OverviewWorkingApplicationsDescriptionAdvantages of the ball millVarietiesSee also

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axi

Wikipedia CC-BY-SA 许可下的文字预计阅读时间:8 分钟

Energy efficient cement ball mill from

Overview What we offer Key Benefits Product features Key benefits High reliability over a century of experience with 4000+ ball mills installed globally Large through-flow area ensures low pressure drop across the

Ball Mill (Ball Mills Explained) saVRee saVRee

For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 30-45%). Pulp (crushed ore and water) fills another 15% of the drum’s volume so that the total volume of the drum is 50% charged.

Ball milling: a green technology for the preparation and

Abstract Ball milling is a simple, fast, cost-effective green technology with enormous potential. One of the most interesting applications of this technology in the field of

Ball mill trunnion replacement

teams to ensure reliable mill operation. Ball mill trunnion replacement Suitable for both and non- mills Reduces stress concentrations, minimising the risk of

Integrating geometallurgical ball mill throughput predictions into

2023年2月1日Open access Abstract This article presents a novel approach to integrate a throughput prediction model for the ball mill into short-term stochastic production

Batch Ball Mill for Open or Closed Circuit Grinding

Technical Data Batch Ball Mill Details The batch ball mill is a kind of ball milling machine which discharges the material in one time according to the nature of the material. Different from continuous ball mill, batch type ball

Ball Mill an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11). The feed can be

Ball Mill at Thomas Scientific

Ball Mill found in: High Energy Ball Mill Emax, Planetary Ball Mill, Gear-Drive 2-Liter Planetary Ball Mills, 8000D Mixer/Mill®, 8000M Mixer/Mill, Gear.. VQ-N ball mills may be referred to as shaker mills, mixer mills or high-energy ball mills. They can be used for both wet and dry grinding as well as to mix a variety of solids,

Kinetic Energy Dose as a Unified Metric for Comparing Ball Mills

2022年1月3日Mechanochemistry utilizes mechanical forces to activate chemical bonds. It offers environmentally benign routes for both (bio) organic and inorganic syntheses. However, direct comparison of mechanochemistry results is often very challenging. In mechanochemical synthetic protocols, ball mill setup (mechanical design and grinding

Ball Mill Ball Mills WetDry Grinding DOVE

DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h-1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity

Ball milling: a green technology for the preparation and

The formation of cellulose crystals by ball mill assisted hydrolysis was also reported by Tian and co-workers, who described the preparation of microcrystalline cellulose (MCC) from eucalyptus pulp by mercerization and subsequent ball mill treatment. 44 The pulp was first treated with sodium hydroxide, then milled in the presence of the same at 450 rpm for 5

High Energy Ball Mill For Sale Vertical Ball Milling Machine

MSE Supplies carries a wide variety of options for both vertical milling machines, planetary and high-energy ball mills for sale. Call Us: +1 (520)789-6673 Sign in or Create an Account. Search. Cart 0. Search. Home; Products Arc Melters and

Integrating geometallurgical ball mill throughput predictions into

2023年2月1日Open access Abstract This article presents a novel approach to integrate a throughput prediction model for the ball mill into short-term stochastic production scheduling in mining complexes.

Ball Mill an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11). The feed can be dry, with less than 3% moisture to minimize ball coating, or

What Is a Ball Mill? Blog Posts OneMonroe

2020年3月10日Overview of Ball Mills. As shown in the adjacent image, a ball mill is a type grinding machine that uses balls to grind and remove material. It consists of a hollow compartment that rotates along a

Process engineering with planetary ball mills

Planetary ball mills are well known and used for particle size reduction on laboratory and pilot scales for decades while during the last few years the application of planetary ball mills has extended to mechanochemical

Ball milling as an important pretreatment technique in

2021年8月12日Both attrition and planetary ball mills were effective to reduce particle size, minimize waste generation, and loss of biomass, as compared to tumbling ball mill . Licari et al. used different mechanical deconstruction methods (tumbler ball mill, vibratory ball mill, centrifugal mill, and jet mill) for pretreatment of gold cane bagasse.

Ball Mill at Thomas Scientific

Ball Mill found in: High Energy Ball Mill Emax, Planetary Ball Mill, Gear-Drive 2-Liter Planetary Ball Mills, 8000D Mixer/Mill®, 8000M Mixer/Mill, Gear.. VQ-N ball mills may be referred to as shaker mills, mixer mills or high-energy ball mills. They can be used for both wet and dry grinding as well as to mix a variety of solids,

Kinetic Energy Dose as a Unified Metric for Comparing Ball Mills

2022年1月3日Mechanochemistry utilizes mechanical forces to activate chemical bonds. It offers environmentally benign routes for both (bio) organic and inorganic syntheses. However, direct comparison of mechanochemistry results is often very challenging. In mechanochemical synthetic protocols, ball mill setup (mechanical design and grinding

Ball Mill Ball Mills WetDry Grinding DOVE

DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h-1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity

Ball milling: a green technology for the preparation and

Abstract Ball milling is a simple, fast, cost-effective green technology with enormous potential. One of the most interesting applications of this technology in the field of cellulose is the preparation and the chemical modification of cellulose nanocrystals and nanofibers.

Integrating geometallurgical ball mill throughput predictions into

2023年2月1日Open access Abstract This article presents a novel approach to integrate a throughput prediction model for the ball mill into short-term stochastic production scheduling in mining complexes.

Ball Mill an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11). The feed can be dry, with less than 3% moisture to minimize ball coating, or

AMIT 135: Lesson 7 Ball MillsCircuits Mining

Objectives At the end of this lesson students should be able to: Explain the role of ball mill in mineral industry and why it is extensively used. Describe different types of ball mill design. Describe the components of ball mill.

Small Ball Mill 911 Metallurgist

The ball mill, an intermediate and fine-grinding device, is a tumbling drum with a 40% to 50% filling of balls. The material that is to be ground fills the voids between the balls. The tumbling balls capture the particles in

What Is a Ball Mill? Blog Posts OneMonroe

2020年3月10日Overview of Ball Mills. As shown in the adjacent image, a ball mill is a type grinding machine that uses balls to grind and remove material. It consists of a hollow compartment that rotates along a

Ball milling as an important pretreatment technique in

2021年8月12日Both attrition and planetary ball mills were effective to reduce particle size, minimize waste generation, and loss of biomass, as compared to tumbling ball mill . Licari et al. used different mechanical deconstruction methods (tumbler ball mill, vibratory ball mill, centrifugal mill, and jet mill) for pretreatment of gold cane bagasse.

Ball mill Wikipedia

OverviewWorkingApplicationsDescriptionAdvantages of the ball millVarietiesSee also

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axi

Energy efficient cement ball mill from

Overview What we offer Key Benefits Product features Key benefits High reliability over a century of experience with 4000+ ball mills installed globally Large through-flow area ensures low pressure drop across the

Ball Mill (Ball Mills Explained) saVRee saVRee

For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 30-45%). Pulp (crushed ore and water) fills another 15% of the drum’s volume so that the total volume of the drum is 50% charged.

Ball milling: a green technology for the preparation and

Abstract Ball milling is a simple, fast, cost-effective green technology with enormous potential. One of the most interesting applications of this technology in the field of

Ball mill trunnion replacement

teams to ensure reliable mill operation. Ball mill trunnion replacement Suitable for both and non- mills Reduces stress concentrations, minimising the risk of

Integrating geometallurgical ball mill throughput predictions into

2023年2月1日Open access Abstract This article presents a novel approach to integrate a throughput prediction model for the ball mill into short-term stochastic production

Batch Ball Mill for Open or Closed Circuit Grinding

Technical Data Batch Ball Mill Details The batch ball mill is a kind of ball milling machine which discharges the material in one time according to the nature of the material. Different from continuous ball mill, batch type ball

Ball Mill an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11). The feed can be

Ball Mill at Thomas Scientific

Ball Mill found in: High Energy Ball Mill Emax, Planetary Ball Mill, Gear-Drive 2-Liter Planetary Ball Mills, 8000D Mixer/Mill®, 8000M Mixer/Mill, Gear.. VQ-N ball mills may be referred to as shaker mills, mixer mills or high-energy ball mills. They can be used for both wet and dry grinding as well as to mix a variety of solids,

Kinetic Energy Dose as a Unified Metric for Comparing Ball Mills

2022年1月3日Mechanochemistry utilizes mechanical forces to activate chemical bonds. It offers environmentally benign routes for both (bio) organic and inorganic syntheses. However, direct comparison of mechanochemistry results is often very challenging. In mechanochemical synthetic protocols, ball mill setup (mechanical design and grinding

Ball Mill Ball Mills WetDry Grinding DOVE

DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h-1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity

Ball milling: a green technology for the preparation and

The formation of cellulose crystals by ball mill assisted hydrolysis was also reported by Tian and co-workers, who described the preparation of microcrystalline cellulose (MCC) from eucalyptus pulp by mercerization and subsequent ball mill treatment. 44 The pulp was first treated with sodium hydroxide, then milled in the presence of the same at 450 rpm for 5

High Energy Ball Mill For Sale Vertical Ball Milling Machine

MSE Supplies carries a wide variety of options for both vertical milling machines, planetary and high-energy ball mills for sale. Call Us: +1 (520)789-6673 Sign in or Create an Account. Search. Cart 0. Search. Home; Products Arc Melters and

Integrating geometallurgical ball mill throughput predictions into

2023年2月1日Open access Abstract This article presents a novel approach to integrate a throughput prediction model for the ball mill into short-term stochastic production scheduling in mining complexes.

Ball Mill an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11). The feed can be dry, with less than 3% moisture to minimize ball coating, or

What Is a Ball Mill? Blog Posts OneMonroe

2020年3月10日Overview of Ball Mills. As shown in the adjacent image, a ball mill is a type grinding machine that uses balls to grind and remove material. It consists of a hollow compartment that rotates along a

Process engineering with planetary ball mills

Planetary ball mills are well known and used for particle size reduction on laboratory and pilot scales for decades while during the last few years the application of planetary ball mills has extended to mechanochemical

Ball milling as an important pretreatment technique in

2021年8月12日Both attrition and planetary ball mills were effective to reduce particle size, minimize waste generation, and loss of biomass, as compared to tumbling ball mill . Licari et al. used different mechanical deconstruction methods (tumbler ball mill, vibratory ball mill, centrifugal mill, and jet mill) for pretreatment of gold cane bagasse.

Ball Mill at Thomas Scientific

Ball Mill found in: High Energy Ball Mill Emax, Planetary Ball Mill, Gear-Drive 2-Liter Planetary Ball Mills, 8000D Mixer/Mill®, 8000M Mixer/Mill, Gear.. VQ-N ball mills may be referred to as shaker mills, mixer mills or high-energy ball mills. They can be used for both wet and dry grinding as well as to mix a variety of solids,

Kinetic Energy Dose as a Unified Metric for Comparing Ball Mills

2022年1月3日Mechanochemistry utilizes mechanical forces to activate chemical bonds. It offers environmentally benign routes for both (bio) organic and inorganic syntheses. However, direct comparison of mechanochemistry results is often very challenging. In mechanochemical synthetic protocols, ball mill setup (mechanical design and grinding

Ball Mill Ball Mills WetDry Grinding DOVE

DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h-1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity

Ball milling: a green technology for the preparation and

Abstract Ball milling is a simple, fast, cost-effective green technology with enormous potential. One of the most interesting applications of this technology in the field of cellulose is the preparation and the chemical modification of cellulose nanocrystals and nanofibers.

Integrating geometallurgical ball mill throughput predictions into

2023年2月1日Open access Abstract This article presents a novel approach to integrate a throughput prediction model for the ball mill into short-term stochastic production scheduling in mining complexes.

Ball Mill an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11). The feed can be dry, with less than 3% moisture to minimize ball coating, or

AMIT 135: Lesson 7 Ball MillsCircuits Mining

Objectives At the end of this lesson students should be able to: Explain the role of ball mill in mineral industry and why it is extensively used. Describe different types of ball mill design. Describe the components of ball mill.

Small Ball Mill 911 Metallurgist

The ball mill, an intermediate and fine-grinding device, is a tumbling drum with a 40% to 50% filling of balls. The material that is to be ground fills the voids between the balls. The tumbling balls capture the particles in

What Is a Ball Mill? Blog Posts OneMonroe

2020年3月10日Overview of Ball Mills. As shown in the adjacent image, a ball mill is a type grinding machine that uses balls to grind and remove material. It consists of a hollow compartment that rotates along a

Ball milling as an important pretreatment technique in

2021年8月12日Both attrition and planetary ball mills were effective to reduce particle size, minimize waste generation, and loss of biomass, as compared to tumbling ball mill . Licari et al. used different mechanical deconstruction methods (tumbler ball mill, vibratory ball mill, centrifugal mill, and jet mill) for pretreatment of gold cane bagasse.

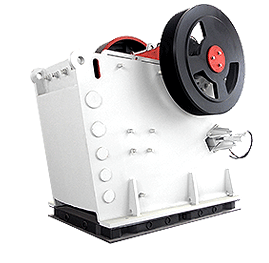

كسارة الفك المواد

عايزين نشوف احدث معدات ثقيلة

tagtag المحفوظات آلة محطم

بريستيج ألترا جولد بالإضافة إلى سعر المطحنة

أسود الحديد آلات طحن أكسيد مصنعين

ليزينيثن طحن آلة للبيع في ماليزيا

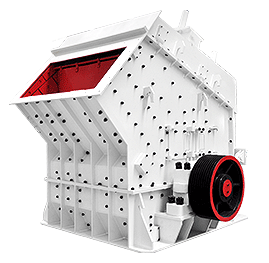

مصنع كسارة تصادم بيرو

خط تولید سنگ کارخانه سنگ شکن

قائمة أسعار معدات التكسير مع الملحقات

مصنع تكسير 200 طن ph من ألمانيا

جميع شركات كسارة j amp k

تعدين الذهب في خريطة بوركينا فاسو

المستخدمة معالجة خام مصنع

تهتز الشاشة ليرة سورية

فاصل المغناطيسي الأوكرانية غاوس

أعلى جودة مطحنة الكرة السيراميك المطلي من المورد الصين موثوق

ماكينات صناعه البلاط الموزايكو

منجم الذهب الأفريقي والمصفاة باني ش

المخدرات خلط آلة التصنيع

تجهیزات آسیاب در هند

كساره متحركه CBM

شاشات كسارة متحركه للبيع جنوب افريقيا

ما حل وجع الطاحونه

الفلسبار سحق آلات السودان

في إكوادور هناك شركات تصنيع الآلات لسحق

المشترين محطة كسارة حجر في تنزانيا

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20