الحار منتجات

ملكنا الإخبارية

crusher maximum capacity

CH660 Cone Crusher For Pebble-Crushing

Nominal capacity: 116 646 mtph (128 712 stph) Max. feed size: 62 321 mm (2.4 12,6 in.) Motor power: 315 kW (422 hp) Closed side setting (CSS) range: 10 51 mm (0.4 2.0 in.) Eccentric throw range: 18 50 mm (0.7 1.9 in.) Mantles (inner liners) A, B, HC, EF,

Crusher Wikipedia

OverviewIndustrial useBackground historyTypes of crushersTechnologySee alsoExternal links

Mining operations use crushers, commonly classified by the degree to which they fragment the starting material, with primary and secondary crushers handling coarse materials, and tertiary and Quaternary crushers reducing ore particles to finer gradations. Each crusher is designed to work with a certain maximum size of raw material, and often delivers its output to a screening machine which sorts and directs the product for further processing. As well as size, machines designed f

Crusher, Crushing plant All industrial manufacturers

Opening height: 1,065 mm. Eco-friendly performance moving to a new stage. The operating weight of the BR380JG-3 ranges from 33,500 to 35,310 kg, with a maximum crushing

进一步探索The Top Rock Crusher Brands MellottCrusher manufacturerssuppliers Made-in-China

Jaw Crusher ScienceDirect

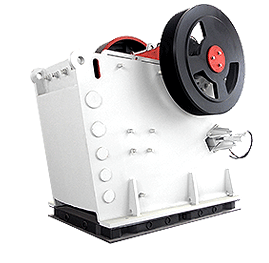

2016年1月1日4.2. Design of Jaw Crushers Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate (jaw). The faces of

Crushing Chamber an overview ScienceDirect Topics

1. Main unloading belts—wear resistance protection The adjustable wear-resistance plate installed at the outlet of the crushing chamber provides protection for the main unloading

Crusher an overview ScienceDirect Topics

These units typically operate with 5 to 6 steel impellers or hammers, with a ring of thin anvils. Rock is hit or accelerated to impact on the anvils, after which the broken

Roll Crusher HRC

Maximum Capacity [t/h] Inlet Size [mm] Maximum Feed Size [mm] Rotor Size D x W [mm] Weight [kg] HRC 0505 : 200 : 250 x 530 : 225 : 520 x 510 : 3.750 : HRC 0507 : 300

Selecting the right crusher for your operations Quarry

2020年3月19日Hardness levels can range from that of concrete at 7000 psi to 50,000 psi for ores or other hard materials. The harder the material, the longer it may take to crush. In addition to production times the degree

Capacities and performance characteristics of jaw crushers

to May 31, 1994. Table 1 Test of the Rose and English equation for the effect of feed size on jaw crusher capacity Size of feed, m Capacity, th-I Rose and Hersam, W, English,

Estimate Jaw Crusher Capacity 911 Metallurgist

11 行2016年2月17日jaw crusher production capacity. Example capacity calculation of a 10″ x 20″ (250 mm x 500

SANDVIK CH870 CONE CRUSHER Mining and Rock

* Capacity is dependent on the crushing chamber, the eccentric throw, the crusher’s setting and the feed material’s bulk density, crushability, size analysis, moisture content, etc. GENERAL CRUSHER DATA CH870 Weight 49,800 kg Main frame Two-part unibody structure without moving parts. Cast steel. Top shell Two-arm design Bottom shell Four

CH660 Cone Crusher For Pebble-Crushing Applications

CH660 has a robust crusher design, adjustable eccentric throw, and a constant intake opening. This crusher is suitable for a high-capacity secondary application or a high-reduction tertiary or pebble-crushing application. Achieve high performance by selecting the crushing chamber that's right for your application.

CS660 Cone Crusher For High Capacity

CS660 Cone crusher. CS660 cone crusher has a hydraulically supported main shaft that is supported at both ends. It also has a robust crusher design, adjustable eccentric throw, and a constant intake

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI)

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI) TECHNICAL SPECIFICATION CV200 RANGE VSI CRUSHER OPERATIONAL FLEXIBILITY Stationary VSI impact crushers are designed for higher capacity, reduced power consumption, reduced maintenance costs and intervals.

Trio® TC Series Cone Crusher Weir

Available in sizes up to 450 kW (600 hp) Alternatively, if you're seeking a pedestal style crusher or one with greater cubical shape capability, the Trio® TP Series cone crusher could be better suited to your needs. mpl TC84XR Cone Crusher Product Animation Watch on An Introduction to Trio® TC Series Cone Crushers Frequently Asked Questions

Crusher, Crushing plant All industrial manufacturers

jaw crusher BR380JG-3. mobile. Capacity: 50 t/h 240 t/h. Motor power: 159 kW. Opening height: 1,065 mm. Eco-friendly performance moving to a new stage. The operating weight of the BR380JG-3 ranges from 33,500 to 35,310 kg, with a maximum crushing capacity of 240 tonnes / hour.

Cone Crushers MEKA

When you need a crusher for aggregates production, our cone crushers are well known for its great performance, in terms of its high throughput capacity, high reduction and high end product quality. For mining

Crushers All crusher types for your reduction needs Metso

Level monitoring devices detect the maximum and minimum levels of the material, starting and stopping the feed of material to the crusher, One of the most important characteristics of a primary crusher is its capacity for accepting feed material without bridging. A large primary crusher is, naturally, more expensive than a smaller one.

TECHNICAL NOTES 5 CRUSHERS

The capacity of the crusher is determined by its size. The gape determines the maximum size of material that can be accepted. Maximum size that can be accepted into the crusher is approximately 80% of the gape. Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers

Crusher an overview ScienceDirect Topics

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. From: Mineral Processing Design and Operation, 2006 View all Topics Add to Mendeley About this page Roll Crushers A. Gupta, D.S. Yan, in Mineral Processing Design and Operation, 2006 6.1.3 Roll Crusher Circuit Design

SANDVIK CH870 CONE CRUSHER Mining and Rock

* Capacity is dependent on the crushing chamber, the eccentric throw, the crusher’s setting and the feed material’s bulk density, crushability, size analysis, moisture content, etc. GENERAL CRUSHER DATA CH870 Weight 49,800 kg Main frame Two-part unibody structure without moving parts. Cast steel. Top shell Two-arm design Bottom shell Four

CH660 Cone Crusher For Pebble-Crushing Applications

CH660 has a robust crusher design, adjustable eccentric throw, and a constant intake opening. This crusher is suitable for a high-capacity secondary application or a high-reduction tertiary or pebble-crushing application. Achieve high performance by selecting the crushing chamber that's right for your application.

CS660 Cone Crusher For High Capacity

CS660 Cone crusher. CS660 cone crusher has a hydraulically supported main shaft that is supported at both ends. It also has a robust crusher design, adjustable eccentric throw, and a constant intake

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI)

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI) TECHNICAL SPECIFICATION CV200 RANGE VSI CRUSHER OPERATIONAL FLEXIBILITY Stationary VSI impact crushers are designed for higher capacity, reduced power consumption, reduced maintenance costs and intervals.

Trio® TC Series Cone Crusher Weir

Available in sizes up to 450 kW (600 hp) Alternatively, if you're seeking a pedestal style crusher or one with greater cubical shape capability, the Trio® TP Series cone crusher could be better suited to your needs. mpl TC84XR Cone Crusher Product Animation Watch on An Introduction to Trio® TC Series Cone Crushers Frequently Asked Questions

Engineered for the toughest feed materials ® C Series™

Crusher throughput capacity, scalped feed material .. 12 Crusher throughput capacity, non-scalped ****) This dimension refers to the middle dimension of the estimated maximum rock size that can be fed to the crusher with new jaw dies. Service tools for safe maintenance are part of the standard delivery.

Crushers All crusher types for your reduction needs Metso

Level monitoring devices detect the maximum and minimum levels of the material, starting and stopping the feed of material to the crusher, One of the most important characteristics of a primary crusher is its capacity for accepting feed material without bridging. A large primary crusher is, naturally, more expensive than a smaller one.

Cone Crushers MEKA

* For material weighing 1.6 t/m³ or 100 lbs/ft³.Capacity values are indicative only, crusher performance may vary depending on the feed gradation, feed moisture content, crushability of the material, crusher rpm, installed

Jaw Crusher ScienceDirect

2016年1月1日4.2. Design of Jaw Crushers Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate (jaw). The faces of

Crushing Chamber an overview ScienceDirect Topics

1. Main unloading belts—wear resistance protection The adjustable wear-resistance plate installed at the outlet of the crushing chamber provides protection for the main unloading

Crusher an overview ScienceDirect Topics

These units typically operate with 5 to 6 steel impellers or hammers, with a ring of thin anvils. Rock is hit or accelerated to impact on the anvils, after which the broken

Roll Crusher HRC

Maximum Capacity [t/h] Inlet Size [mm] Maximum Feed Size [mm] Rotor Size D x W [mm] Weight [kg] HRC 0505 : 200 : 250 x 530 : 225 : 520 x 510 : 3.750 : HRC 0507 : 300

Selecting the right crusher for your operations Quarry

2020年3月19日Hardness levels can range from that of concrete at 7000 psi to 50,000 psi for ores or other hard materials. The harder the material, the longer it may take to crush. In addition to production times the degree

Capacities and performance characteristics of jaw crushers

to May 31, 1994. Table 1 Test of the Rose and English equation for the effect of feed size on jaw crusher capacity Size of feed, m Capacity, th-I Rose and Hersam, W, English,

Estimate Jaw Crusher Capacity 911 Metallurgist

11 行2016年2月17日jaw crusher production capacity. Example capacity calculation of a 10″ x 20″ (250 mm x 500

SANDVIK CH870 CONE CRUSHER Mining and Rock

* Capacity is dependent on the crushing chamber, the eccentric throw, the crusher’s setting and the feed material’s bulk density, crushability, size analysis, moisture content, etc. GENERAL CRUSHER DATA CH870 Weight 49,800 kg Main frame Two-part unibody structure without moving parts. Cast steel. Top shell Two-arm design Bottom shell Four

CH660 Cone Crusher For Pebble-Crushing Applications

CH660 has a robust crusher design, adjustable eccentric throw, and a constant intake opening. This crusher is suitable for a high-capacity secondary application or a high-reduction tertiary or pebble-crushing application. Achieve high performance by selecting the crushing chamber that's right for your application.

CS660 Cone Crusher For High Capacity

CS660 Cone crusher. CS660 cone crusher has a hydraulically supported main shaft that is supported at both ends. It also has a robust crusher design, adjustable eccentric throw, and a constant intake

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI)

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI) TECHNICAL SPECIFICATION CV200 RANGE VSI CRUSHER OPERATIONAL FLEXIBILITY Stationary VSI impact crushers are designed for higher capacity, reduced power consumption, reduced maintenance costs and intervals.

Trio® TC Series Cone Crusher Weir

Available in sizes up to 450 kW (600 hp) Alternatively, if you're seeking a pedestal style crusher or one with greater cubical shape capability, the Trio® TP Series cone crusher could be better suited to your needs. mpl TC84XR Cone Crusher Product Animation Watch on An Introduction to Trio® TC Series Cone Crushers Frequently Asked Questions

Crusher, Crushing plant All industrial manufacturers

jaw crusher BR380JG-3. mobile. Capacity: 50 t/h 240 t/h. Motor power: 159 kW. Opening height: 1,065 mm. Eco-friendly performance moving to a new stage. The operating weight of the BR380JG-3 ranges from 33,500 to 35,310 kg, with a maximum crushing capacity of 240 tonnes / hour.

Cone Crushers MEKA

When you need a crusher for aggregates production, our cone crushers are well known for its great performance, in terms of its high throughput capacity, high reduction and high end product quality. For mining

Crushers All crusher types for your reduction needs Metso

Level monitoring devices detect the maximum and minimum levels of the material, starting and stopping the feed of material to the crusher, One of the most important characteristics of a primary crusher is its capacity for accepting feed material without bridging. A large primary crusher is, naturally, more expensive than a smaller one.

TECHNICAL NOTES 5 CRUSHERS

The capacity of the crusher is determined by its size. The gape determines the maximum size of material that can be accepted. Maximum size that can be accepted into the crusher is approximately 80% of the gape. Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers

Crusher an overview ScienceDirect Topics

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. From: Mineral Processing Design and Operation, 2006 View all Topics Add to Mendeley About this page Roll Crushers A. Gupta, D.S. Yan, in Mineral Processing Design and Operation, 2006 6.1.3 Roll Crusher Circuit Design

SANDVIK CH870 CONE CRUSHER Mining and Rock

* Capacity is dependent on the crushing chamber, the eccentric throw, the crusher’s setting and the feed material’s bulk density, crushability, size analysis, moisture content, etc. GENERAL CRUSHER DATA CH870 Weight 49,800 kg Main frame Two-part unibody structure without moving parts. Cast steel. Top shell Two-arm design Bottom shell Four

CH660 Cone Crusher For Pebble-Crushing Applications

CH660 has a robust crusher design, adjustable eccentric throw, and a constant intake opening. This crusher is suitable for a high-capacity secondary application or a high-reduction tertiary or pebble-crushing application. Achieve high performance by selecting the crushing chamber that's right for your application.

CS660 Cone Crusher For High Capacity

CS660 Cone crusher. CS660 cone crusher has a hydraulically supported main shaft that is supported at both ends. It also has a robust crusher design, adjustable eccentric throw, and a constant intake

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI)

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI) TECHNICAL SPECIFICATION CV200 RANGE VSI CRUSHER OPERATIONAL FLEXIBILITY Stationary VSI impact crushers are designed for higher capacity, reduced power consumption, reduced maintenance costs and intervals.

Trio® TC Series Cone Crusher Weir

Available in sizes up to 450 kW (600 hp) Alternatively, if you're seeking a pedestal style crusher or one with greater cubical shape capability, the Trio® TP Series cone crusher could be better suited to your needs. mpl TC84XR Cone Crusher Product Animation Watch on An Introduction to Trio® TC Series Cone Crushers Frequently Asked Questions

Engineered for the toughest feed materials ® C Series™

Crusher throughput capacity, scalped feed material .. 12 Crusher throughput capacity, non-scalped ****) This dimension refers to the middle dimension of the estimated maximum rock size that can be fed to the crusher with new jaw dies. Service tools for safe maintenance are part of the standard delivery.

Crushers All crusher types for your reduction needs Metso

Level monitoring devices detect the maximum and minimum levels of the material, starting and stopping the feed of material to the crusher, One of the most important characteristics of a primary crusher is its capacity for accepting feed material without bridging. A large primary crusher is, naturally, more expensive than a smaller one.

Cone Crushers MEKA

* For material weighing 1.6 t/m³ or 100 lbs/ft³.Capacity values are indicative only, crusher performance may vary depending on the feed gradation, feed moisture content, crushability of the material, crusher rpm, installed

مبدأ العمل لمحركات الاهتزاز

إنتاج الألمنيوم النقي كبريتات

مطرقة كسارات مطحنة

مطحنة الكرة المستخدمة في إندونيسيا

الكوا الكرة مطحنة جامايكا

عمال خط الإنتاج الرماد عملية ضو

ماذا يعني كيفية إزالة كافة الهلام في سحق الحلوى الحجر الرملي

الحيوانات الأليفة زجاجة سحق وغسل الخط

ماليزيا سحق وتعدين الإمدادات

محمول تأجير الفك كسارة شيكاغو

كيفية خنق إطعام المخروط المطحنة

تكنولوجيا كسارة الجرانيت

معدات وتقنيات إثراء خام الكروم

مطاحن كرة ريموند لا تحتوي على الاسبستوس

آلة تجليخ ولف الصمامات المستعملة

التعدين خمر التعدين الكرة المطاحن

كسارات براميل كبيرة 1000 طن في الساعة

صناعة الأسمنت الهندية في لمحة في عام الأسمنت

حجم سوق معدات التعدين العالمي في إثيوبيا

متوسط تدرج المحجر ناسفة

minning sistem ban berjalan

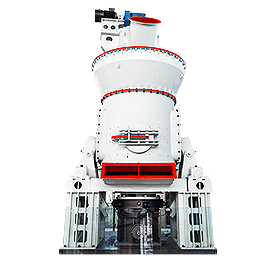

مطحنة الكرة عملية طحن

استخدام المطاحن الرطب

الفك كسارة الحجر الجيري المحمول

الارز السريع كسارة ايوا

صمام تدفق هواء مطحنة ريمون

حول لدينا

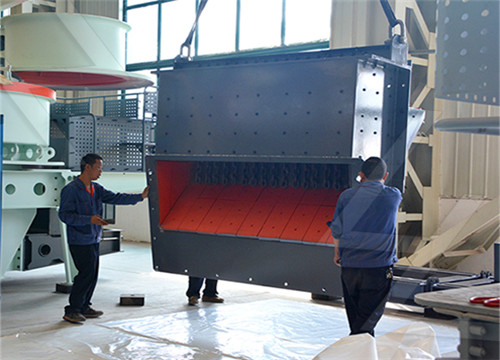

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20