الحار منتجات

ملكنا الإخبارية

rock crushing and grainding

Use of drilling performance to improve rock-breakage

2020年3月1日Crushing and grinding are some of the most energy-intensive industrial processes in the world. In mines, rock-breakage (comminution) processes comprise a

Pre-treatment of rocks prior to comminution ScienceDirect

2017年3月1日Crushing and grinding marginally differ from the fact that crushing liberates particles in coarser size ranges whereas grinding in finer size ranges.

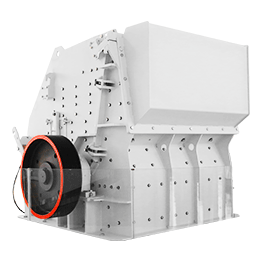

Rock Crusher MachinesPulverizers Williams Crusher

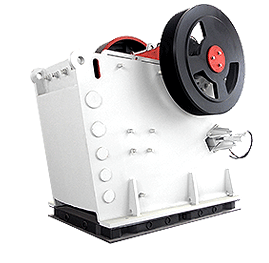

A rock crusher is a device used to crush rocks into pieces of your desired size. Rock crushers are most often used for gravel, sand, and other building applications. Some of the most common types of aggregates in rock

ETHZ D-ERDW Crushing and grinding a rock YouTube

2022年9月5日How to use the rock crushinggrinding laboratory at ETH Zürich / D-ERDW. Video by Lydia Zehnder and Michael Fux (c) ETH Zürich, Dept. Earth Sciences,

(PDF) The Effects of Blasting on Crushing and Grinding

2003年1月1日This stone examines the role blasting plays in optimum crushing and grinding with the emphasis on energy reduction. The role of different blasting energy input on fragmentation is studied, and

Rock breakage by crushing, blasting, and drilling ScienceDirect

Both crushing and grinding refer to particle size reduction; the principal difference between these two designations is that grinding implies smaller mean particle sizes. The ability of

Crushing in Mineral Processing 911 Metallurgist

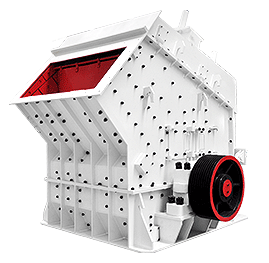

2015年12月26日In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wear-resistant plate/surface. Less abrasive and softer rocks or stones are crushed by impact and

What is the size limit between crushing and grinding?

Crushing breaks the large particles into multiple pieces and the aim is to facilitate easy transportation and storage. Generally +20 mm is acceptable for crushing. Grinding is a

Crushing and Grinding WetSticky Ore 911 Metallurgist

2016年5月9日A washing section is a “must” in all operations handling wet, sticky ore. This facilitates ore handling, crushing, and also affords a means for separation of primary slimes and increasing grinding capacity. These

Mineral processing Metallurgy, Crushing

See all related content →. mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after

Use of drilling performance to improve rock-breakage efficiencies:

2020年3月1日Crushing and grinding are some of the most energy-intensive industrial processes in the world. In mines, rock-breakage (comminution) processes comprise a major portion–about 30%-60%–of the total energy consumption [1], [2], [3], [4], [5]. These processes impact not only energy consumption but also mine productivity.

Pre-treatment of rocks prior to comminution ScienceDirect

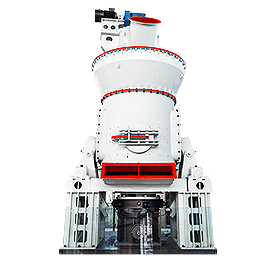

2017年3月1日Crushing and grinding marginally differ from the fact that crushing liberates particles in coarser size ranges whereas grinding in finer size ranges. Grinding is deemed as an indispensable method of comminution for separation of minerals from gangue producing cleaner concentrate.

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material. Grinding equipment

Rock breakage by crushing, blasting, and drilling ScienceDirect

A better understanding of brittle fracture is needed to provide a more valid theoretical basis for comminution studies. INTRODUCTION Comminution commonly refers to the size reduction of rock particles; it specifically denotes crushing and grinding but can also be applied to blasting and drilling (N.A.S.-N.R.C., 1966; CHEATHAM, 1966).

(PDF) SIZE REDUCTION BY GRINDING METHODS

2017年3月4日SIZE REDUCTION BY GRINDING METHODS March 2017 DOI: 10.13140/RG.2.2.21484.56961 Report number: 5 Affiliation: University of Mysore Authors: A. Balasubramanian University of Mysore Abstract

What is the size limit between crushing and grinding?

Ankit . Indian Institute of Technology Kharagpur The difference is ore specific. Crushing is employed as first step in size reduction and the may consists of 2-3 substeps. Crushing breaks the...

Cement Quarrying, Blasting, Beneficiation, and

Manufacture of cement. There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a

Crushing and Grinding WetSticky Ore 911

2016年5月9日Crushing and Grinding WetSticky Ore In the handling of wet, sticky ores such as encountered in tropical areas having distinct dry and rainy seasons, the crushing plant is a section of the mill which must

Use of drilling performance to improve rock-breakage efficiencies:

2020年3月1日Crushing and grinding are some of the most energy-intensive industrial processes in the world. In mines, rock-breakage (comminution) processes comprise a major portion–about 30%-60%–of the total energy consumption [1], [2], [3], [4], [5]. These processes impact not only energy consumption but also mine productivity.

(PDF) Overview of Mineral Processing Methods

2015年8月3日Size reduction typically involved crushing, grinding, and screening (Balasubramanian, 2015) and various separation techniques were employed dependant on the mineral of interest.

(PDF) Rock mechanics related to mining

2017年10月17日To accomplish the two missions, rock mechanics faces following challenges: (1) how to make drilling, crushing and grinding more efficiently, in particular for grinding whose energy...

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material. Grinding equipment

Rock breakage by crushing, blasting, and drilling ScienceDirect

A better understanding of brittle fracture is needed to provide a more valid theoretical basis for comminution studies. INTRODUCTION Comminution commonly refers to the size reduction of rock particles; it specifically denotes crushing and grinding but can also be applied to blasting and drilling (N.A.S.-N.R.C., 1966; CHEATHAM, 1966).

(PDF) SIZE REDUCTION BY GRINDING METHODS

2017年3月4日SIZE REDUCTION BY GRINDING METHODS March 2017 DOI: 10.13140/RG.2.2.21484.56961 Report number: 5 Affiliation: University of Mysore Authors: A. Balasubramanian University of Mysore Abstract

AMIT 135: Lesson 5 Crushing Mining Mill Operator

Crushers have more efficient transfer of applied power to the breakage of rock than grinding mills. Typically a crushing flowsheet for a mineral processing plant will have from one-to-three stages of crushing. There

Cement Quarrying, Blasting, Beneficiation, and

There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the

كسارة فكية عالية الجودة الصين كسارة آلة تركيا كسارة

المورد آلات إعادة تدوير المعادن

تجهیزات معدن میلیارد

والنباتات محطم المستخدمة غسالات

مطاحن يدوية قديمة للبيع في العراق

كفاءة معدات عالية تأثير رمح سحق العمودية ملموسة

المعادن سحق ماهاراشترا آلة

عملية فصل خام الحديد

كسارات الحجر الماس نافي مومباي تعدين الفحم

معدن منیزیم در دولومیت

نوع الحجر سعر محطم محطم المحجر س

تمويل مصنع التعدين سحق

انزلاق حساب قوة الحزام الناقل

3r3216 صغيرة ريمون مطحنة سعر ريمون مطحنة للبيع

ماكينة تقطيع سكين آلة طحن

ماكينات الكرة الرملية في بنغالور

كسارة حجر البازلت وحدة

للبيع مطحنة عمودية عشر

كسارة فكية من الجرانيت 150 tph

ركاز النحاس المحمولة آلة معالجة التركيز

طبل محطم لتر الخرسانة

وظائف في مجال الصحة والعافية

ماكنة ازالة الشعر بالشمع

هيئة اسطوانة وطاحونة سطح الرأس

كسارة فكية لعمال منجم ترفيهي

مصنع كسارة مخروطية متنقلة من الدولوميت

حول لدينا

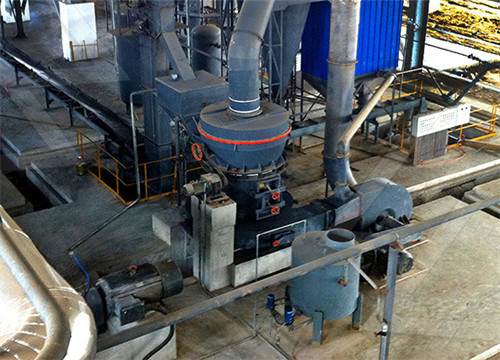

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20