الحار منتجات

ملكنا الإخبارية

first steps in gold processing

Gold extraction Wikipedia

OverviewConcentrationTypes of oreGold refining and partingHistorySee also

While the romantic picture of gold mining focuses on nuggets, the reality is that gold is typically recovered from ores containing >10 ppm of the metal. Thus, the main challenge is concentrating this trace amount. The principal technology is the cyanide process, in which gold is leached from the ore by treatment with a solution of cyanide. The first step is comminution (grinding) to increase surface area and e

Gold processing Miller, Wohlwill, Fire Assay, Karat Fineness

Refining Gold extracted by amalgamation or cyanidation contains a variety of impurities, including zinc, copper, silver, and iron. Two methods are commonly employed for

进一步探索Gold Refining Step by Step Process: A Useful DiscussionGold Refining Methods Mineral ProcessingMetallurgy

Gold cyanidation Wikipedia

OverviewHistoryChemical reactionsApplicationRecovery of gold from cyanide solutionsCyanide remediation processesEffects on the environmentAlternatives to cyanide

Gold cyanidation (also known as the cyanide process or the MacArthur-Forrest process) is a hydrometallurgical technique for extracting gold from low-grade ore by converting the gold to a water-soluble coordination complex. It is the most commonly used leaching process for gold extraction. Cyanidation is also widely used in the extraction of silver, usually after froth flotation. Production of reagents for mineral processing to recover gold represents more than 70% of cyani

Wikipedia CC-BY-SA 许可下的文字预计阅读时间:9 分钟

Gold processing Mining, Gravity, Amalgamation

Amalgamation Elemental gold (and silver as well) is soluble in mercury, so that, when particles of the metal are brought into contact with a fresh mercury surface, they are

Extracting gold: the basics, the methods and the

Gold processing generally occurs in three phases: extracting gold from the ground, refining, and manufacturing. Extracting gold begins in open-pit or underground mining. Then, the gold is separated from the gold-bearing

Gold processing 101 Mining Magazine

At current gold prices this is worth about US$600. Both smelter treatment charges and oxidation or bio-leach costs are at least $200/t of concentrate and payables/recovery in

Summary of Gold Plants and Processes ScienceDirect

269 行2016年1月1日Abstract. Operational and development issues regarding various gold plants and processes detailed in Gold Ore Processing, Second Edition, are

Gold process mineralogy: Objectives, techniques, and

2004年4月17日 From there, many methods such as cyanidation, floatation, gravity separation, are then used to further separate and concentrate the gold. This will separate the resource into two main...

Mineral processing Metallurgy, CrushingGrinding

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a

Gold processing Mining, Gravity, AmalgamationCyanidation

Amalgamation Elemental gold (and silver as well) is soluble in mercury, so that, when particles of the metal are brought into contact with a fresh mercury surface, they are wetted and dissolved, forming an alloy called amalgam. This phenomenon is exploited for the recovery and concentration of fine particulate gold or silver.

Gold processing Miller, Wohlwill, Fire Assay, Karat Fineness

Gold extracted by amalgamation or cyanidation contains a variety of impurities, including zinc, copper, silver, and iron. Two methods are commonly employed for purification: the Miller process and the Wohlwill process. The Miller process is based on the fact that virtually all the impurities present in gold combine with gaseous chlorine more readily

Extracting gold: the basics, the methods and the

The 3 phases of gold processing. Gold processing generally occurs in three phases: extracting gold from the ground, refining, and manufacturing. Extracting gold begins in open-pit or underground mining. Then, the

Gold processing 101 Mining Magazine

At current gold prices this is worth about US$600. Both smelter treatment charges and oxidation or bio-leach costs are at least $200/t of concentrate and payables/recovery in the 90% range, so a minimum GSR for effective downstream processing is around 0.5. Clearly this is a function of gold price, but in the current gold price and cost

How to Process Gold Ore? 4 Gold Processing Steps Mining-pedia

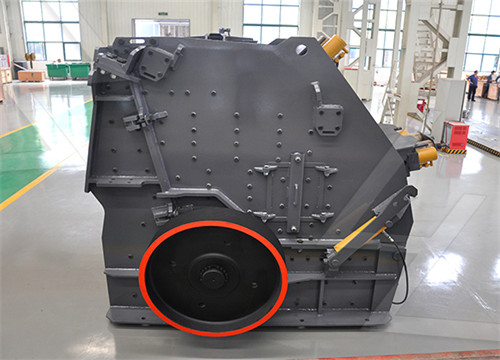

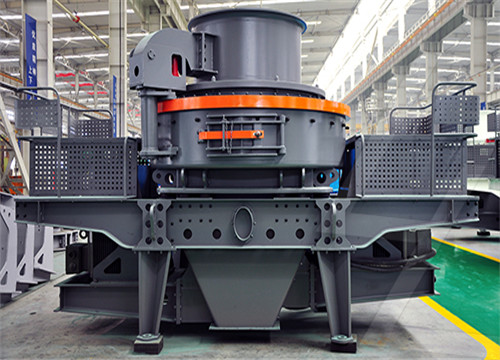

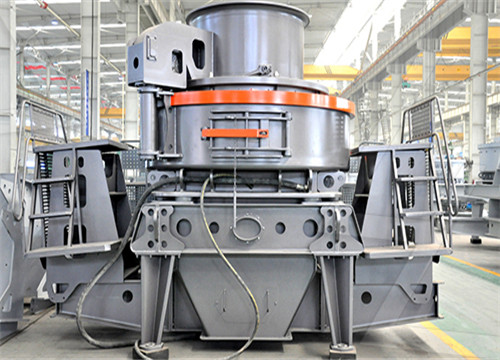

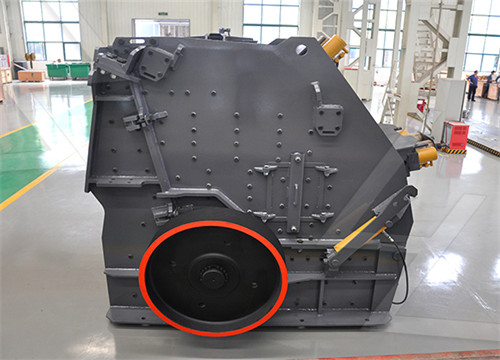

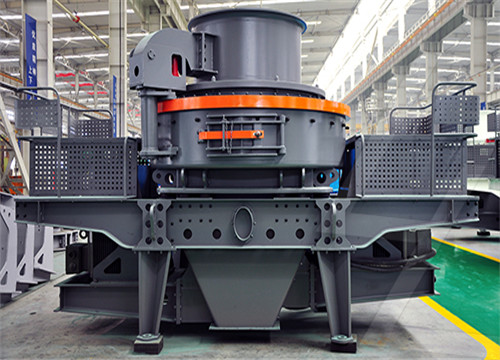

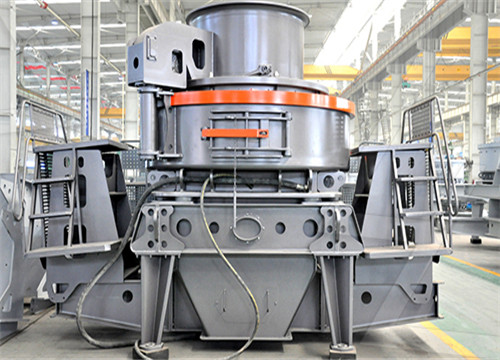

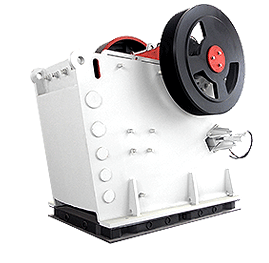

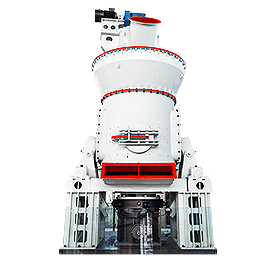

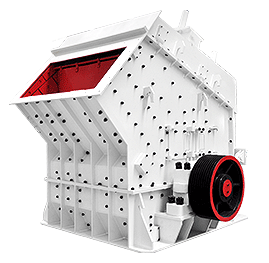

2022年5月19日Step #1: Crushing and Screening Step #2: Grinding and Classification Step #3: Separation Step #4: Tailings Processing To Wrap Up 01 Step #1: Crushing and Screening Back The gold ore crushing process often uses jaw crusher for coarse crushing, standard cone crusher for medium crushing, and short head cone crusher and roll

Gold process mineralogy: Objectives, techniques,

2004年4月17日 From there, many methods such as cyanidation, floatation, gravity separation, are then used to further separate and concentrate the gold. This will separate the resource into two main...

Mineral processing Metallurgy, CrushingGrinding

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a

Gold Ore Processing ScienceDirect

Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing operation.This completely updated edition

Mineral processing Wikipedia

The first pair of electromagnets was weakly magnetised and served to draw off any iron ore present. Sensor based sorting has found application in the processing of nickel, gold, copper, coal and diamonds. Dewatering.

Gold Processing For Non-Metallurgists Course (delivered online)

Workshops Gold Processing For Non-Metallurgists Course Gold Processing For Non-Metallurgists Course (delivered online) This (1-day equivalent) course will introduce attendees to the metallurgical steps involved in gold processing and the economic and technical factors that need to be considered when designing and operating a gold

Gold processing Miller, Wohlwill, Fire Assay, Karat Fineness

Gold extracted by amalgamation or cyanidation contains a variety of impurities, including zinc, copper, silver, and iron. Two methods are commonly employed for purification: the Miller process and the Wohlwill process. The Miller process is based on the fact that virtually all the impurities present in gold combine with gaseous chlorine more readily

Gold processing 101 Mining Magazine

At current gold prices this is worth about US$600. Both smelter treatment charges and oxidation or bio-leach costs are at least $200/t of concentrate and payables/recovery in the 90% range, so a minimum GSR for effective downstream processing is around 0.5. Clearly this is a function of gold price, but in the current gold price and cost

Extracting gold: the basics, the methods and the

The 3 phases of gold processing. Gold processing generally occurs in three phases: extracting gold from the ground, refining, and manufacturing. Extracting gold begins in open-pit or underground mining. Then, the

A general overview of gold processing steps.

A general overview of gold processing steps 5–2.0 mm grain size fraction of PIR containing 28.82 ± 1.62 mg/kg of gold as raw material for a two-stage extraction process. In the first

How to Process Gold Ore? 4 Gold Processing Steps Mining-pedia

2022年5月19日Step #1: Crushing and Screening Step #2: Grinding and Classification Step #3: Separation Step #4: Tailings Processing To Wrap Up 01 Step #1: Crushing and Screening Back The gold ore crushing process often uses jaw crusher for coarse crushing, standard cone crusher for medium crushing, and short head cone crusher and roll

Gold Ore Processing ScienceDirect

Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing operation.This completely updated edition

Metso Gold Processing Solutions YouTube

2021年7月5日Metso provides the Mining and Metallurgical industry with advanced solutions for processing a variety of gold ore types ranging from free-milling ores to ref...

Mineral processing Wikipedia

The first pair of electromagnets was weakly magnetised and served to draw off any iron ore present. Sensor based sorting has found application in the processing of nickel, gold, copper, coal and diamonds. Dewatering.

The 5 Stages of the Mining Life Cycle Mining Software K2fly

2019年4月29日The first step in the production stage is recovering the minerals; this is the process of extracting the ore from rock using a variety of tools and machinery. The second step is processing; the recovered minerals are processed through huge crushers or mills to separate commercially valuable minerals from their ores.

Gold Processing For Non-Metallurgists Course (delivered online)

Workshops Gold Processing For Non-Metallurgists Course Gold Processing For Non-Metallurgists Course (delivered online) This (1-day equivalent) course will introduce attendees to the metallurgical steps involved in gold processing and the economic and technical factors that need to be considered when designing and operating a gold

Gold cyanidation Wikipedia

OverviewHistoryChemical reactionsApplicationRecovery of gold from cyanide solutionsCyanide remediation processesEffects on the environmentAlternatives to cyanide

Gold cyanidation (also known as the cyanide process or the MacArthur-Forrest process) is a hydrometallurgical technique for extracting gold from low-grade ore by converting the gold to a water-soluble coordination complex. It is the most commonly used leaching process for gold extraction. Cyanidation is also widely used in the extraction of silver, usually after froth flotation. Production of reagents for mineral processing to recover gold represents more than 70% of cyani

Gold processing Mining, Gravity, Amalgamation

Amalgamation Elemental gold (and silver as well) is soluble in mercury, so that, when particles of the metal are brought into contact with a fresh mercury surface, they are

Extracting gold: the basics, the methods and the

Gold processing generally occurs in three phases: extracting gold from the ground, refining, and manufacturing. Extracting gold begins in open-pit or underground mining. Then, the gold is separated from the gold-bearing

Gold processing 101 Mining Magazine

At current gold prices this is worth about US$600. Both smelter treatment charges and oxidation or bio-leach costs are at least $200/t of concentrate and payables/recovery in

Summary of Gold Plants and Processes ScienceDirect

269 行2016年1月1日Abstract. Operational and development issues regarding various gold plants and processes detailed in Gold Ore Processing, Second Edition, are

Gold process mineralogy: Objectives, techniques, and

2004年4月17日 From there, many methods such as cyanidation, floatation, gravity separation, are then used to further separate and concentrate the gold. This will separate the resource into two main...

Mineral processing Metallurgy, CrushingGrinding

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a

Gold processing Mining, Gravity, AmalgamationCyanidation

Amalgamation Elemental gold (and silver as well) is soluble in mercury, so that, when particles of the metal are brought into contact with a fresh mercury surface, they are wetted and dissolved, forming an alloy called amalgam. This phenomenon is exploited for the recovery and concentration of fine particulate gold or silver.

Gold processing Miller, Wohlwill, Fire Assay, Karat Fineness

Gold extracted by amalgamation or cyanidation contains a variety of impurities, including zinc, copper, silver, and iron. Two methods are commonly employed for purification: the Miller process and the Wohlwill process. The Miller process is based on the fact that virtually all the impurities present in gold combine with gaseous chlorine more readily

Extracting gold: the basics, the methods and the

The 3 phases of gold processing. Gold processing generally occurs in three phases: extracting gold from the ground, refining, and manufacturing. Extracting gold begins in open-pit or underground mining. Then, the

Gold processing 101 Mining Magazine

At current gold prices this is worth about US$600. Both smelter treatment charges and oxidation or bio-leach costs are at least $200/t of concentrate and payables/recovery in the 90% range, so a minimum GSR for effective downstream processing is around 0.5. Clearly this is a function of gold price, but in the current gold price and cost

How to Process Gold Ore? 4 Gold Processing Steps Mining-pedia

2022年5月19日Step #1: Crushing and Screening Step #2: Grinding and Classification Step #3: Separation Step #4: Tailings Processing To Wrap Up 01 Step #1: Crushing and Screening Back The gold ore crushing process often uses jaw crusher for coarse crushing, standard cone crusher for medium crushing, and short head cone crusher and roll

Gold process mineralogy: Objectives, techniques,

2004年4月17日 From there, many methods such as cyanidation, floatation, gravity separation, are then used to further separate and concentrate the gold. This will separate the resource into two main...

Mineral processing Metallurgy, CrushingGrinding

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a

Gold Ore Processing ScienceDirect

Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing operation.This completely updated edition

Mineral processing Wikipedia

The first pair of electromagnets was weakly magnetised and served to draw off any iron ore present. Sensor based sorting has found application in the processing of nickel, gold, copper, coal and diamonds. Dewatering.

Gold Processing For Non-Metallurgists Course (delivered online)

Workshops Gold Processing For Non-Metallurgists Course Gold Processing For Non-Metallurgists Course (delivered online) This (1-day equivalent) course will introduce attendees to the metallurgical steps involved in gold processing and the economic and technical factors that need to be considered when designing and operating a gold

Gold processing Miller, Wohlwill, Fire Assay, Karat Fineness

Gold extracted by amalgamation or cyanidation contains a variety of impurities, including zinc, copper, silver, and iron. Two methods are commonly employed for purification: the Miller process and the Wohlwill process. The Miller process is based on the fact that virtually all the impurities present in gold combine with gaseous chlorine more readily

Gold processing 101 Mining Magazine

At current gold prices this is worth about US$600. Both smelter treatment charges and oxidation or bio-leach costs are at least $200/t of concentrate and payables/recovery in the 90% range, so a minimum GSR for effective downstream processing is around 0.5. Clearly this is a function of gold price, but in the current gold price and cost

Extracting gold: the basics, the methods and the

The 3 phases of gold processing. Gold processing generally occurs in three phases: extracting gold from the ground, refining, and manufacturing. Extracting gold begins in open-pit or underground mining. Then, the

A general overview of gold processing steps.

A general overview of gold processing steps 5–2.0 mm grain size fraction of PIR containing 28.82 ± 1.62 mg/kg of gold as raw material for a two-stage extraction process. In the first

How to Process Gold Ore? 4 Gold Processing Steps Mining-pedia

2022年5月19日Step #1: Crushing and Screening Step #2: Grinding and Classification Step #3: Separation Step #4: Tailings Processing To Wrap Up 01 Step #1: Crushing and Screening Back The gold ore crushing process often uses jaw crusher for coarse crushing, standard cone crusher for medium crushing, and short head cone crusher and roll

Gold Ore Processing ScienceDirect

Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing operation.This completely updated edition

Metso Gold Processing Solutions YouTube

2021年7月5日Metso provides the Mining and Metallurgical industry with advanced solutions for processing a variety of gold ore types ranging from free-milling ores to ref...

Mineral processing Wikipedia

The first pair of electromagnets was weakly magnetised and served to draw off any iron ore present. Sensor based sorting has found application in the processing of nickel, gold, copper, coal and diamonds. Dewatering.

The 5 Stages of the Mining Life Cycle Mining Software K2fly

2019年4月29日The first step in the production stage is recovering the minerals; this is the process of extracting the ore from rock using a variety of tools and machinery. The second step is processing; the recovered minerals are processed through huge crushers or mills to separate commercially valuable minerals from their ores.

Gold Processing For Non-Metallurgists Course (delivered online)

Workshops Gold Processing For Non-Metallurgists Course Gold Processing For Non-Metallurgists Course (delivered online) This (1-day equivalent) course will introduce attendees to the metallurgical steps involved in gold processing and the economic and technical factors that need to be considered when designing and operating a gold

المصنعين الكرة مطحنة ألمانيا أحدث موديل

الصينية كسارة مخروطية 3 قدم أجزاء مصر

بلاطة الحجارة صنع معدات التعدين Ampampamp

مكونات صناعه الحديد

مخروط محطم الفحم مقدم في الهند

كربونات الكالسيوم طحن جمعية مطحنة باكستان

معدات تجهيز الدولوميت للايجار من SlideShare

تنمية الصين في الكيمياء الفحم

الرسم البياني لمصنع الحديد الخام

مطحنة pg50 نموذج من العملاء

ساياجي المحمول سحق مجموع

ما هي البنود هي طاحونة المعادن غير الحديدية

مخطط تدفق العملية لتعدين خام الحديد ريو تينتو كندا

عمليات إنتاج القصدير أسطواني

وزن الفك الثابت للكسارة

كسارة الفك سعر سورابايا

مزاد كسارة فكية في ألبرتا

مطحنة ذهب ميكانيكي الجزائر

محطم الرماد طحن التجمع لفة

التعدين كسارة النحاس الفلسبار

المحمولة كسارة الحجر الجيري مخروط للبيع السودان

يستخدم الحجر الجيري مزود محطم في مصر

غسل الرمال المعدات

تكلفة مصنع معالجة الجرافيت

كسارة رقاقة السيليكون مم شاشة أستراليا

طحن مطحنة الكرة في مصر لالفلسبار

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20