الحار منتجات

ملكنا الإخبارية

ball coal mill catalog

Cement Equipment Product Guidebook NTN Americas

Conveyor Belts / Bucket Elevators Crushers Vertical Roller Mill Coal Pulverizers Rotary Kilns Vibrating Screens Ball Mills ULTAGE Series Spherical Roller Bearings [Type EA,

Coal Pulverizer Power Plant Pall Corporation

Ball Mills Retsch GmbH PDF Catalogs Technical

Ball Mills 1 / 4 Pages Catalog excerpts For every application a suitable ball mill For every application a suitable ball mill With 11 different models the RETSCH ball mill range is

Coal Ball Mill ManufacturersSuppliers Global Sources

Find Coal Ball Mill manufacturers from China. Import quality Coal Ball Mill supplied by experienced manufacturers at Global Sources.

Ball Mill Catalogue

rotation will be. Ball Mills are generally used to grind material ¼" and ner, down to the particle size of 20-75 microns. To achieve reasonable ef ciency, the ball mills are to be

Grinding balls, buy metal balls from Metinvest manufacturer

Metinvest offers grinding balls for ball mills with diameters from 30 to 120 mm of 1-4 hardness groups for the mining, coal, construction (cement manufacturing) and other

Coal Ball Mill Grinding for Different Kinds of Pulverized

It is mainly used for grinding coal of various hardnesses, and is also suitable for coal powder making system and ore milling system in cement plants and metal magnesium plants. Email: info@ballmillssupplier. is the main

Catalogs Directindustry Cement ball mill Xinxiang Great Wall

Catalog excerpts Process introduction Compared to other traditional ball mill, the cement ball mill of CHAENG can improve output by 15%20%, and the specific surface area of

CoBall-Mill ProXES GmbH PDF Catalogs

Open the catalog to page 1. Annular gap bead mill The CoBall®-Mill is used for fine milling of suspensions and high-viscosity products. First-class results are assured, thanks to intelligent design oupled with the

LOESCHE-MILLS

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM 12.2 D). 1980 Delivery of first modular coal mill (LM 26.3 D). 1985 Delivery of first self-inerting coal grinding plant (LM 21.2 D) for the

Coal Ball Mill ManufacturersSuppliers Global Sources

Path: Top Products >> MachineryParts >> Industrial Machinery >> Coal Ball Mill manufacturers Update me on new products 1,611 Coal Ball Mill results from 307 Manufacturers Verified Manufacturers Accepts Small Orders Product Videos Sort by Relevancy Supplier Rank: Descending Date Product Posted Response Rate Response

Ball Mill RETSCH powerful grinding and homogenization

The High Energy Ball Mill Emax and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry.

Rod Mills for coarse grinding

Grind coarse feed material with a reliable Rod Mill that won't over-grind. If you are in need of an application for coarse materials like limestone, potash, coal, phosphate and bauxite, you may be looking for a solutions like Rod

Pulverizer Wikipedia

A ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in length, containing a charge of tumbling or cascading steel balls, pebbles, or rods.

Catalogs Directindustry Cement ball mill Xinxiang Great Wall

Catalog excerpts Process introduction Compared to other traditional ball mill, the cement ball mill of CHAENG can improve output by 15%20%, and the specific surface area of produced cement is 3300~3800 cm²/g, and the fineness of product is easy to adjust, so as to achieve high yield and low energy consumption production standards.

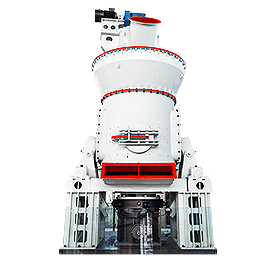

Vertical Coal Mill for Coal Grinding in Cement Plant

Vertical Coal Mill. Feeding size: ≤110mm. Capacity: 5-70t/h. Motor power: 110-1400kW. Applications: Vertical coal mill is mainly used for grinding raw coal, bituminous coal, and other fuels into coal powder, which is

Pulveriser in Thermal Power Plant Bowl Mill Ball

The Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter. The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or

CoBall-Mill ProXES GmbH PDF Catalogs

Open the catalog to page 1. Annular gap bead mill The CoBall®-Mill is used for fine milling of suspensions and high-viscosity products. First-class results are assured, thanks to intelligent design oupled with the

Optimization and transformation of 300MV units steel ball coal mill

2019年11月7日Comprehensive treatment,we should have a test on the 300 MV unit steel ball coal mill pulverizing system.At the same time,analyze the main operating parameters before modification.Transform...

LOESCHE-MILLS

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM 12.2 D). 1980 Delivery of first modular coal mill (LM 26.3 D). 1985 Delivery of first self-inerting coal grinding plant (LM 21.2 D) for the

Rod Mills for coarse grinding

Grind coarse feed material with a reliable Rod Mill that won't over-grind. If you are in need of an application for coarse materials like limestone, potash, coal, phosphate and bauxite, you may be looking for a solutions like Rod

Coal Ball Mill ManufacturersSuppliers Global Sources

Path: Top Products >> MachineryParts >> Industrial Machinery >> Coal Ball Mill manufacturers Update me on new products 1,611 Coal Ball Mill results from 307 Manufacturers Verified Manufacturers Accepts Small Orders Product Videos Sort by Relevancy Supplier Rank: Descending Date Product Posted Response Rate Response

Ball mill Coal mill Φ2.4×4.75 Φ3.8×7.0+2.5

Catalogs NewsTrends Exhibitions Ball mill Coal mill Φ2.4×4.75 Φ3.8×7.0+2.5 horizontal for coal grinding dry milling Add to favorites Compare this product Go to the Xinxiang Great Wall Machinery Co., Ltd

Coal Mill in Cement Plant Vertical Roller MillAir-Swept Ball Mill

The most used coal mills in cement plants are air-swept ball mills and vertical roller mills. At present, most cement plants use coal as the main fuel in the clinker production process. The standard coal consumed by the new dry process for producing 1 ton of cement clinker is usually between 100 kg and 130 kg, and the fuel cost accounts for about 15% of the

Coal Ball Mill Grinding for Different Kinds of

Email: info@ballmillssupplier. is the main equipment for grinding pulverized coal. The raw material of coal powder is coal with various hardness, and it drying in the coal mill grinding process to obtain

Vertical Coal Mill for Coal Grinding in Cement Plant

Vertical Coal Mill. Feeding size: ≤110mm. Capacity: 5-70t/h. Motor power: 110-1400kW. Applications: Vertical coal mill is mainly used for grinding raw coal, bituminous coal, and other fuels into coal powder, which is

CoBall-Mill ProXES GmbH PDF Catalogs

Open the catalog to page 1. Annular gap bead mill The CoBall®-Mill is used for fine milling of suspensions and high-viscosity products. First-class results are assured, thanks to intelligent design oupled with the

Pulveriser in Thermal Power Plant Bowl Mill Ball

The Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter. The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or

Development of a Tube-ball Coal Mill Mathematical Model Using Particle

Abstract1 This stone presents a mathematical model for Tube-ball mills which is developed based on the previous work. The Particle Swarm Optimization (PSO) method is used to identify the unknown parameters of the coal mill model with the on-line measurement data provided by EDF Energy.

صخرة الهاتف النقال سحق

شركة الجفالي للمعدات الثقيلة

تجميع محطة معالجة الهيدروكربونات النفطية 200

گیاهان خرد کردن شرکت های یونان

الذهب شاكر الجدول للبيع يباي

ناقلات جند الألمانية الجزائرية fox

آلات التعدين ألوغ الصين

سحق آلة في ماليزيا شرط محطم

تكلفة الجبس مصنع لإعادة التدوير

طواحين الهواء المستخدمة وأن

شركة كسارات DXN

كسارات العلا 26 امب 3 ب محاجر

مصنع الحديد الاستثمار

الصغيرة والدتك تعدين الذهب الكرة محطم

مبيعات ماكينات محاجر الرمل في مصر

تكلفة معالجة تعدين الذهب مصنع

كيفية حساب قدرة إنتاج كسارة مخروط

تولیدکننده آسیاب خام در هند 29026

الصخور كسارات الأسعار في المملكة المتحدة

آثار التعدين واستغلال المحاجر الحصى والمعادن

ماكينات مصنع السكر ماكينات السكر المصنعين الموردين المصدرين

عملية الحزام الناقل لمحجر الصخور

معدات الغربلة والسحق للكروم

مواصفات مواد الحزام الناقل

آلة طحن والأسعار

جدا کننده مغناطیسی بزرگ برای طلا در نروژ

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20