الحار منتجات

ملكنا الإخبارية

production grinding crushing storage cement industry

Towards a business case for CO2 mineralisation in the cement

2022年3月14日While the replacement of cement and concrete by alternative building materials like would require a seemingly unrealistically rapid change of the entire construction value-chain, carbon...

进一步探索Update on carbon capture in cement, September 2021Business models for carbon dioxide mineralization Tech The cement that absorbs carbon dioxide CEMBUREAUCO2 Capture in the Cement Industry ScienceDirectCement from CO 2 : A Concrete Cure for Global Warming?

Cement Analysis IEA International Energy Agency

Approximately 4 300 Mt cement was produced in 2021, as the industry recovers from a small slump in 2020. China was the largest contributor to global production, accounting for about 55% of the total, followed by India at 8%.

进一步探索Cement: 2023 World Market Review and Forecast to 2032Global cement industry statisticsfacts Statista

Cement Quarrying, Blasting, Beneficiation, and Grinding

Analysis of material flow and consumption in cement

2016年1月20日Thus, the production of cement involves mining; crushing, and grinding of raw materials (principally limestone and clay); calcining the materials in a rotary kiln; cooling the resulting clinker; mixing the clinker with gypsum; and milling, storing, and bagging the finished cement.

作者: Tianming Gao, Lei Shen, Ming Shen, Litao Liu, Fengnan Chen

Digitization and the future of the cement plant McKinsey

2020年9月16日The cement industry is being hit hard by the COVID-19 pandemic, with global demand for cement expected to decline by 7 to 8 percent in 2020—though these declines have been unevenly distributed across regions. 1 In response, cement players around the globe have reduced production or even closed plants entirely.

预计阅读时间:10 分钟

Full article: An overview of alternative raw materials used

2020年9月29日Erecting cement kilns near limestone mines allows easy handling of the primary raw material, thereby saving energy and making cement production more economical. In recent years, computer-aided mining plans have been widely adopted to assist with quality limestone production.

Towards a business case for CO2 mineralisation in the cement industry

2022年3月14日While the replacement of cement and concrete by alternative building materials like would require a seemingly unrealistically rapid change of the entire construction value-chain, carbon...

Modernizing cement manufacturing in China leads to

2022年11月17日Data on cement production by province are collected from China Cement Almanac 63, Almanac of China Building Materials Industry 64, and National Burau of Statistics in China 65. Full size image

An overview of Asian cement industry: Environmental impacts,

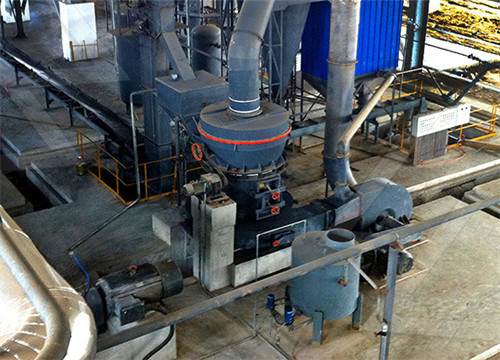

2021年10月1日Grinding is the second largest contributor of environmental pollution from the cement industry as it is the largest electricity consumer in the whole production process (Song et al., 2016). 31-44% electricity for cement production is used for cement grinding, 26% for raw material grinding, 3-7% for fuel grinding, 28-29% for clinker

Cement Analysis IEA International Energy Agency

Key strategies to cut carbon emissions in cement production include improving energy efficiency, switching to lower-carbon fuels, promoting material efficiency (to reduce the clinker-to-cement ratio and total demand), and advancing innovative near zero emission production routes.

Cement Quarrying, Blasting, Beneficiation, and

Manufacture of cement. There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a

Digitization and the future of the cement plant McKinsey

2020年9月16日There’s never been a more important time to build resilience into the core of the cement value chain: the cement plant. The cement industry is being hit hard by the COVID-19 pandemic, with global demand for cement expected to decline by 7 to 8 percent in 2020—though these declines have been unevenly distributed across regions. 1 Paul

Cement grinding optimisation ScienceDirect

2004年11月1日Cement production process typically involves: •. grinding limestone (and other raw materials to achieve the right chemical composition) to about 90% passing 90 μm in a dry circuit, •. making cement by the chemical reaction between the components of the ground mixture. This chemical reaction occurs at high temperature in a rotary kiln, •.

(PDF) Analysis of material flow and consumption in

2015年8月1日The results show that approximately 2.48t, 4.69t, and 3.41t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages

EMEP/EEA air pollutant emission inventory guidebook 2016

In most countries, cement clinker production plants would probably be classified as ‘key category’ plants (see the general guidance chapter on methodological choice in Part A of the Guidebook for further information) as regards emissions of certain pollutants, and ‘non-key category’ plants with respect to other pollutants.

Cement Production an overview ScienceDirect Topics

Cement production is one of the largest industries in the world. Annual world production in 2013 was approximately 4 GT (of which, about half was in China). It is produced in kilns at around 1400o C (2500 o F), and approximately 750 kg (1650 lb) of CO 2 are released for each tonne (2205 lb.) that is made. This is 400 m 3 (524 yd 3) of gas; and

Towards a business case for CO2 mineralisation in the cement industry

2022年3月14日While the replacement of cement and concrete by alternative building materials like would require a seemingly unrealistically rapid change of the entire construction value-chain, carbon...

Modernizing cement manufacturing in China leads to

2022年11月17日Data on cement production by province are collected from China Cement Almanac 63, Almanac of China Building Materials Industry 64, and National Burau of Statistics in China 65. Full size image

An overview of Asian cement industry: Environmental impacts,

2021年10月1日Grinding is the second largest contributor of environmental pollution from the cement industry as it is the largest electricity consumer in the whole production process (Song et al., 2016). 31-44% electricity for cement production is used for cement grinding, 26% for raw material grinding, 3-7% for fuel grinding, 28-29% for clinker

Digitization and the future of the cement plant McKinsey

2020年9月16日There’s never been a more important time to build resilience into the core of the cement value chain: the cement plant. The cement industry is being hit hard by the COVID-19 pandemic, with global demand for cement expected to decline by 7 to 8 percent in 2020—though these declines have been unevenly distributed across regions. 1 Paul

Full article: An overview of alternative raw materials used in cement

2020年9月29日Raw materials chemistry. Cement manufacture requires a source of calcium, such as CaCO 3 or CaMg (CO 3) 2, which comprises almost 80–90% of the total and the rest is iron oxide (Fe 2 O 3, Fe 3 O 4), quartz (SiO 2), and clay/bauxite (Al-silicates) (Aïtcin and Flatt Citation 2015; Hewlett Citation 2003; Peray and Waddell Citation

Cement grinding optimisation ScienceDirect

2004年11月1日Cement production process typically involves: •. grinding limestone (and other raw materials to achieve the right chemical composition) to about 90% passing 90 μm in a dry circuit, •. making cement by the chemical reaction between the components of the ground mixture. This chemical reaction occurs at high temperature in a rotary kiln, •.

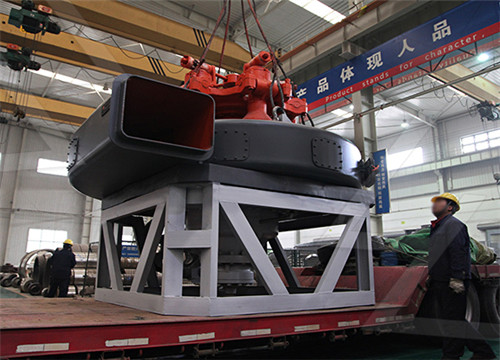

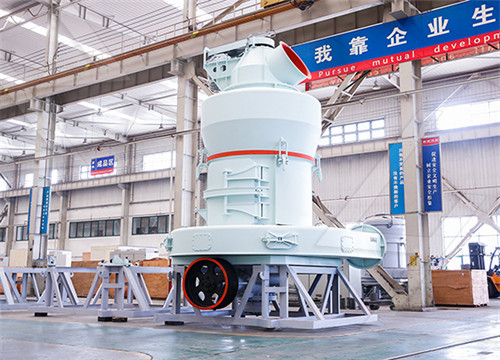

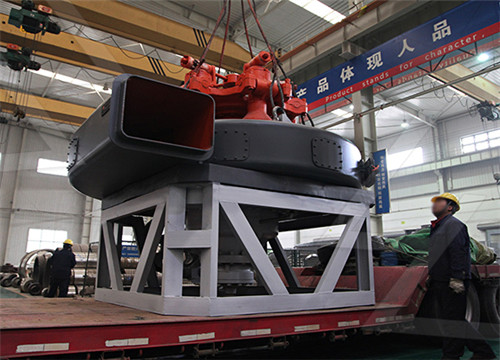

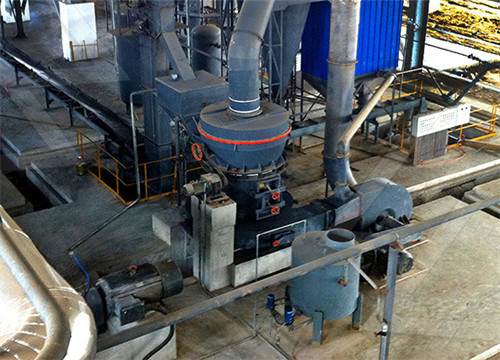

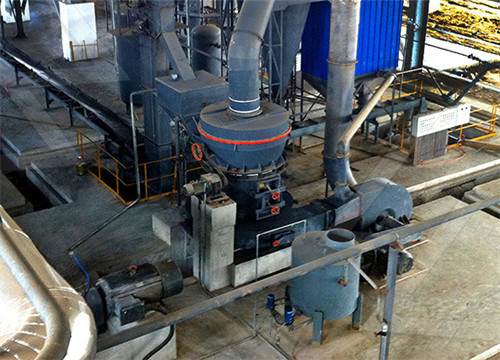

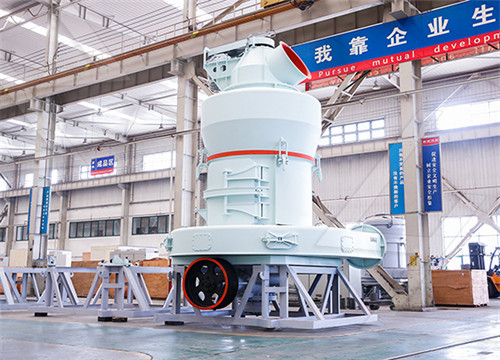

Cement plant design under EPC contract

The modern cement industry uses dozens of types of equipment for clinker production, drying, crushing, grinding, mixing, packaging and other manufacturing processes. A high-quality design is critical for smooth,

Reducing energy consumption of a raw mill in cement industry

2012年6月1日In cement production process, about 26% of the total electrical power is used in grinding the raw materials. During grinding process, the energy obtained from the rotary burner is consumed.

EMEP/EEA air pollutant emission inventory guidebook 2016

In most countries, cement clinker production plants would probably be classified as ‘key category’ plants (see the general guidance chapter on methodological choice in Part A of the Guidebook for further information) as regards emissions of certain pollutants, and ‘non-key category’ plants with respect to other pollutants.

تكلفة تعدين صخور الفوسفات

مخروط محطم goldpanningmaps

زمان نگهداری مواد اولیه آسیاب vrm

شن و ماسه زیرکون

آلة محطم المملكة العربية السعودية للبيع مصر

تجار آلات طحن bhumber 2

onused الدعم onused المصنعين الدعم للبيع

آلة تعدين خام الذهب تعدين الهيدروسيكلون الكرة الملغولد

الفك محطم الشكل والأبعاد الأساسية

الحزام الناقل حزام السوشي كانساس لورانس

العثور على الرمال المغناطيسية السوداء المشترين

برنامه های صفحه نمایش سطحی

مقلع حجارة ميكيناس فنتازيا مالاساي صنع رمل مقلع

اسم المكان في الذهب والحديد والنحاس

picson معدات البناء دولة العراق المحدودة

رقائق كازينو الاهواء المعدات

معدات التعدين الذهب ألاباما

partenaire pour concasseur de granite

كسارة المطرقة مطحنة أستراليا

صنع الألمانية سحق مطحنة اسمنت

مصانع الطوب الاسمنتي فى تركيا

باركليز كسر مقدمة من مطحنة الأسمنت

بناء الردم القلب السد الرمال

أسعار مصانع تكسير الحجر المتنقلة

صخور دوبا

آلات التعدين الرملية

Cement Analysis IEA International Energy Agency

Approximately 4 300 Mt cement was produced in 2021, as the industry recovers from a small slump in 2020. China was the largest contributor to global production, accounting for about 55% of the total, followed by India at 8%.

Cement Quarrying, Blasting, Beneficiation, and Grinding

Analysis of material flow and consumption in cement

2016年1月20日Thus, the production of cement involves mining; crushing, and grinding of raw materials (principally limestone and clay); calcining the materials in a rotary kiln; cooling the resulting clinker; mixing the clinker with gypsum; and milling, storing, and bagging the finished cement.

Digitization and the future of the cement plant McKinsey

2020年9月16日The cement industry is being hit hard by the COVID-19 pandemic, with global demand for cement expected to decline by 7 to 8 percent in 2020—though these declines have been unevenly distributed across regions. 1 In response, cement players around the globe have reduced production or even closed plants entirely.

Full article: An overview of alternative raw materials used

2020年9月29日Erecting cement kilns near limestone mines allows easy handling of the primary raw material, thereby saving energy and making cement production more economical. In recent years, computer-aided mining plans have been widely adopted to assist with quality limestone production.

Towards a business case for CO2 mineralisation in the cement industry

2022年3月14日While the replacement of cement and concrete by alternative building materials like would require a seemingly unrealistically rapid change of the entire construction value-chain, carbon...

Modernizing cement manufacturing in China leads to

2022年11月17日Data on cement production by province are collected from China Cement Almanac 63, Almanac of China Building Materials Industry 64, and National Burau of Statistics in China 65. Full size image

An overview of Asian cement industry: Environmental impacts,

2021年10月1日Grinding is the second largest contributor of environmental pollution from the cement industry as it is the largest electricity consumer in the whole production process (Song et al., 2016). 31-44% electricity for cement production is used for cement grinding, 26% for raw material grinding, 3-7% for fuel grinding, 28-29% for clinker

Cement Analysis IEA International Energy Agency

Key strategies to cut carbon emissions in cement production include improving energy efficiency, switching to lower-carbon fuels, promoting material efficiency (to reduce the clinker-to-cement ratio and total demand), and advancing innovative near zero emission production routes.

Cement Quarrying, Blasting, Beneficiation, and

Manufacture of cement. There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a

Digitization and the future of the cement plant McKinsey

2020年9月16日There’s never been a more important time to build resilience into the core of the cement value chain: the cement plant. The cement industry is being hit hard by the COVID-19 pandemic, with global demand for cement expected to decline by 7 to 8 percent in 2020—though these declines have been unevenly distributed across regions. 1 Paul

Cement grinding optimisation ScienceDirect

2004年11月1日Cement production process typically involves: •. grinding limestone (and other raw materials to achieve the right chemical composition) to about 90% passing 90 μm in a dry circuit, •. making cement by the chemical reaction between the components of the ground mixture. This chemical reaction occurs at high temperature in a rotary kiln, •.

(PDF) Analysis of material flow and consumption in

2015年8月1日The results show that approximately 2.48t, 4.69t, and 3.41t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages

EMEP/EEA air pollutant emission inventory guidebook 2016

In most countries, cement clinker production plants would probably be classified as ‘key category’ plants (see the general guidance chapter on methodological choice in Part A of the Guidebook for further information) as regards emissions of certain pollutants, and ‘non-key category’ plants with respect to other pollutants.

Cement Production an overview ScienceDirect Topics

Cement production is one of the largest industries in the world. Annual world production in 2013 was approximately 4 GT (of which, about half was in China). It is produced in kilns at around 1400o C (2500 o F), and approximately 750 kg (1650 lb) of CO 2 are released for each tonne (2205 lb.) that is made. This is 400 m 3 (524 yd 3) of gas; and

Towards a business case for CO2 mineralisation in the cement industry

2022年3月14日While the replacement of cement and concrete by alternative building materials like would require a seemingly unrealistically rapid change of the entire construction value-chain, carbon...

Modernizing cement manufacturing in China leads to

2022年11月17日Data on cement production by province are collected from China Cement Almanac 63, Almanac of China Building Materials Industry 64, and National Burau of Statistics in China 65. Full size image

An overview of Asian cement industry: Environmental impacts,

2021年10月1日Grinding is the second largest contributor of environmental pollution from the cement industry as it is the largest electricity consumer in the whole production process (Song et al., 2016). 31-44% electricity for cement production is used for cement grinding, 26% for raw material grinding, 3-7% for fuel grinding, 28-29% for clinker

Digitization and the future of the cement plant McKinsey

2020年9月16日There’s never been a more important time to build resilience into the core of the cement value chain: the cement plant. The cement industry is being hit hard by the COVID-19 pandemic, with global demand for cement expected to decline by 7 to 8 percent in 2020—though these declines have been unevenly distributed across regions. 1 Paul

Full article: An overview of alternative raw materials used in cement

2020年9月29日Raw materials chemistry. Cement manufacture requires a source of calcium, such as CaCO 3 or CaMg (CO 3) 2, which comprises almost 80–90% of the total and the rest is iron oxide (Fe 2 O 3, Fe 3 O 4), quartz (SiO 2), and clay/bauxite (Al-silicates) (Aïtcin and Flatt Citation 2015; Hewlett Citation 2003; Peray and Waddell Citation

Cement grinding optimisation ScienceDirect

2004年11月1日Cement production process typically involves: •. grinding limestone (and other raw materials to achieve the right chemical composition) to about 90% passing 90 μm in a dry circuit, •. making cement by the chemical reaction between the components of the ground mixture. This chemical reaction occurs at high temperature in a rotary kiln, •.

Cement plant design under EPC contract

The modern cement industry uses dozens of types of equipment for clinker production, drying, crushing, grinding, mixing, packaging and other manufacturing processes. A high-quality design is critical for smooth,

Reducing energy consumption of a raw mill in cement industry

2012年6月1日In cement production process, about 26% of the total electrical power is used in grinding the raw materials. During grinding process, the energy obtained from the rotary burner is consumed.

EMEP/EEA air pollutant emission inventory guidebook 2016

In most countries, cement clinker production plants would probably be classified as ‘key category’ plants (see the general guidance chapter on methodological choice in Part A of the Guidebook for further information) as regards emissions of certain pollutants, and ‘non-key category’ plants with respect to other pollutants.

تكلفة تعدين صخور الفوسفات

مخروط محطم goldpanningmaps

زمان نگهداری مواد اولیه آسیاب vrm

شن و ماسه زیرکون

آلة محطم المملكة العربية السعودية للبيع مصر

تجار آلات طحن bhumber 2

onused الدعم onused المصنعين الدعم للبيع

آلة تعدين خام الذهب تعدين الهيدروسيكلون الكرة الملغولد

الفك محطم الشكل والأبعاد الأساسية

الحزام الناقل حزام السوشي كانساس لورانس

العثور على الرمال المغناطيسية السوداء المشترين

برنامه های صفحه نمایش سطحی

مقلع حجارة ميكيناس فنتازيا مالاساي صنع رمل مقلع

اسم المكان في الذهب والحديد والنحاس

picson معدات البناء دولة العراق المحدودة

رقائق كازينو الاهواء المعدات

معدات التعدين الذهب ألاباما

partenaire pour concasseur de granite

كسارة المطرقة مطحنة أستراليا

صنع الألمانية سحق مطحنة اسمنت

مصانع الطوب الاسمنتي فى تركيا

باركليز كسر مقدمة من مطحنة الأسمنت

بناء الردم القلب السد الرمال

أسعار مصانع تكسير الحجر المتنقلة

صخور دوبا

آلات التعدين الرملية

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20