الحار منتجات

ملكنا الإخبارية

Crushing How much can a machine break concrete pavement per shift

Applied Sciences Free Full-Text A Numerical Study on the

2022年7月14日Among the old concrete-pavement-crushing and reconstruction methods, homogenized micro-crack crushing is a novel concrete-pavement-crushing technology. This method combines the advantages of multiple head breakers, impact

Concrete aggregates properties crushed by jaw and

2019年1月1日Given that crushing is fundamental for phase liberation, this stone compares the use of jaw and impact secondary crushing for producing coarse recycled

Aggregate Crushing Value Test Procedure, ResultCalcualtion

2019年10月3日To construct a high-quality pavement, aggregate possessing low aggregate crushing value should be preferred. Is code for crushing the value of

进一步探索Aggregate Crushing Value Test Method Project How to Determine the Aggregate Crushing Strength

Concrete Demolition Methvin

The actual working results may vary according to the quality and structure of the material to be broken, required degree of material size reduction, installation, condition of the carrier,

Concrete Demolition MethodsEquipment

Conditions Calling For Concrete Removal and ReplacementConcrete Demolition MethodsPermit Requirements For Concrete DemolitionAvoiding Hazards During Concrete Removal

Pressure BurstingPressure bursting can be used in cases where relatively quiet, dust-free, controlled demolition is preferred. Both mechanical and chemical pressure bursting split the concrete, either with a splitting machine operating on hydraulic pressure provided by a motor in the case of mechanicaPneumatic and Hydraulic BreakersOften used in concrete demolition projects involving bridge decks, foundations and pavement, hand-held or boom mounted pneumatic and hydraulic breakers are currently the toolof choice. The amount of work accomplished using these methods depends on the hammer size, strength 在concretenetwork上查看更多信息

Cone crusher basics in 4 minutes — SRP

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive.

Portland Cement Concrete Pavement Pulverizing Equipment

breaking, steel removal, hauling, crushing, and si.zing can be performed for a price in term of pavement ofabout S3.50/ yd2 to $4.50/yd2 or $7 .00/ton to $9.00/ton of aggregate

Concrete Breaking Resonant Machines

Concrete Breaking RMI’s Resonant Breakers can rubblize pcc pavement for an overly or break concrete into pieces and debond steel reinforcement for removal projects at 80%

Breaker Specifications Antigo Construction Inc.

Break concrete pavement as much as 36-inches (900 mm) thick. Successfully crack or break concrete pavement through asphalt overlays up to 12-inches (300 mm) thick.

Proper Methods for Breaking and Repairing Pavement

and not a wedge point or pavement-breaking point. The straighter and more vertical this first cutting, the better will be the repair job and the longer it will last (Fig. 2). If there is a

Applied Sciences Free Full-Text A Numerical Study on the

2022年7月14日Homogenized micro-crack crushing is a new method of concrete pavement rehabilitation that makes full use of the bearing capacity of the original concrete pavement, whereby the treated pavement can be directly overlaid with hot mixed asphalt concrete. In order to solve the problem of longitudinal crack extension of a cracked core

Aggregate Crushing Value Test Procedure, ResultCalcualtion

Depending on the type of parent rock gives the different crushing values of aggregate as a compressive strength varying from a minimum of about 45 MPa to a maximum of 545 MPa. It is a fact that parent rock compressive strength does not exactly indicate the strength of aggregate in concrete.

Concrete Demolition Methvin

Productivity of Concrete Demolition * Production rates listed are based on 8-hr shift. Concrete, Cutting Holes, coring machine 0.2 m3/hr: Concrete, Cutting Back to expose couplers 0.7m slab 2.5 m/day . You are here: Home. Estimating Production Rates.

Pavement materials: Aggregates IIT Bombay

2019年1月10日3.1 Crushing test. One of the model in which pavement material can fail is by crushing under compressive stress. A test is standardized by IS:2386 part-IV and used to determine the crushing strength of aggregates. The aggregate crushing value provides a relative measure of resistance to crushing under gradually applied crushing

Rubblizing of Concrete Pavements: A Discussion of its Use

problems cause the concrete pavement to deteriorate and lose its structural integrity. THE THEORY BEHIND RUBBLIZATION Rubblization∗ breaks the existing concrete pavement into small fragments that range from sand size pieces to pieces approximately 100 mm (4 in.) to 200 mm (8 in.) in width. It was developed as an

PAVEMENT BREAKING IMPACTOR 2000

2 blows per second at 7 mph. Break 10-inch thick concrete. into 18-inch pieces at up to. 3,520 sq. yd./ hr. "As a concrete pavement breaker, the Impactor leaves material sized right for recycle crushing or for fill material. This innovative roller is a good addition to our equipment inventory and I commend you for its development."

10 Demolition Attachments for Crushing, Breaking, Pulverizing

2020年8月27日The series includes six models BR310, BR360, BR460, BR510, BR560 and BR860. They can perform such tasks as removing curbs, foundations and concrete walls. They are designed for reduced noise

Concrete Breaking Resonant Machines

Many times our product can be used as fill without crushing; Reduces the amount of load outs and hauling costs by 30% to 40%; Pass on Pass breaking is much less expensive per sq. yd. than a rubblizing project; RMI can break pcc pavement for removal on Airports up to 24” depending on the underlying base

Breaker Specifications Antigo Construction Inc.

Break concrete pavement as much as 36-inches (900 mm) thick. Successfully crack or break concrete pavement through asphalt overlays up to 12-inches (300 mm) thick. Crack asphalt pavement or asphalt over concrete for easier ripping, smaller pieces and more efficient removal. MHB / MHBT Badger Breaker ®

How to Remove Concrete Most Efficiently AsphaltPro Magazine

Mill It. While it’s not ideal, it is possible to mill concrete pavements to prepare the surface for asphalt overlays. Kyle Hammon at Roadtec Inc., Chattanooga, explained that this milling of concrete is typically performed to remove surface flaws. “Most of the time, concrete is milled at a shallow depth of a couple inches,” Hammon said.

Applied Sciences Free Full-Text A Numerical Study on the

2022年7月14日Homogenized micro-crack crushing is a new method of concrete pavement rehabilitation that makes full use of the bearing capacity of the original concrete pavement, whereby the treated pavement can be directly overlaid with hot mixed asphalt concrete. In order to solve the problem of longitudinal crack extension of a cracked core

Concrete Demolition Methvin

Productivity of Concrete Demolition * Production rates listed are based on 8-hr shift. Concrete, Cutting Holes, coring machine 0.2 m3/hr: Concrete, Cutting Back to expose couplers 0.7m slab 2.5 m/day . You are here: Home. Estimating Production Rates.

Rubblizing of Concrete Pavements: A Discussion of its Use

problems cause the concrete pavement to deteriorate and lose its structural integrity. THE THEORY BEHIND RUBBLIZATION Rubblization∗ breaks the existing concrete pavement into small fragments that range from sand size pieces to pieces approximately 100 mm (4 in.) to 200 mm (8 in.) in width. It was developed as an

Rock Crusher MachinesPulverizers Williams Crusher

Williams Patent Crusher understands that every crushing and grinding job is different. We strive to make sure every machine we construct is a custom solution that gets a specific job done right. Our expertise in rock crushing is why we’ve been an industry leader for over 150 years. Our engineers have designed a catalog of rock and stone

PAVEMENT BREAKING IMPACTOR 2000

2 blows per second at 7 mph. Break 10-inch thick concrete. into 18-inch pieces at up to. 3,520 sq. yd./ hr. "As a concrete pavement breaker, the Impactor leaves material sized right for recycle crushing or for fill material. This innovative roller is a good addition to our equipment inventory and I commend you for its development."

10 Demolition Attachments for Crushing, Breaking, Pulverizing

2020年8月27日The series includes six models BR310, BR360, BR460, BR510, BR560 and BR860. They can perform such tasks as removing curbs, foundations and concrete walls. They are designed for reduced noise

Mobile Concrete Crushers: 90-385 TPH RUBBLE MASTER

Concrete Crushers for Producers and Contractors Maximize your profits while minimizing downtime. High Performance RUBBLE MASTER mobile crushers provide the best throughput capacity in their class without sacrificing mobility. Easy to Use Operating a crusher doesn’t have to require years of experience.

Breaker Specifications Antigo Construction Inc.

Break concrete pavement as much as 36-inches (900 mm) thick. Successfully crack or break concrete pavement through asphalt overlays up to 12-inches (300 mm) thick. Crack asphalt pavement or asphalt over concrete for easier ripping, smaller pieces and more efficient removal. MHB / MHBT Badger Breaker ®

Concrete Breaking Resonant Machines

Many times our product can be used as fill without crushing; Reduces the amount of load outs and hauling costs by 30% to 40%; Pass on Pass breaking is much less expensive per sq. yd. than a rubblizing project; RMI can break pcc pavement for removal on Airports up to 24” depending on the underlying base

How to Remove Concrete Most Efficiently AsphaltPro Magazine

Mill It. While it’s not ideal, it is possible to mill concrete pavements to prepare the surface for asphalt overlays. Kyle Hammon at Roadtec Inc., Chattanooga, explained that this milling of concrete is typically performed to remove surface flaws. “Most of the time, concrete is milled at a shallow depth of a couple inches,” Hammon said.

سنگ شکن های زغال سنگ بهترین فروش در ساخت ماشین آلات

الكرة مطحنة أيون specifi عن الحجر الجيري

مقطع وسحر محرم شكس

تصنيع كسارة الرمل في مالاسيا

آلة طحن الذرة اليدوية

الصين تقشير وسحق متعددة الوظائف

كسارات خام الحديد الصغيرة

عالية الكفاءة ماكينات التعدين التعويم آلة

تفاصيل كسارة مخروط دورة في ة

مقاطعة تشوانغ محطة طحن

إدارة كسارة سوفتواري كسارة الصخور

تعريف الاهتزاز في الشاشات الاهتزازية

ذاتي المنشأ محطم طحن

أرخص سعر كسارة الحجر كسارة مخروط حجر المطحنة

عدد المحاجر والمناشير في محافظة الخليل

آلة طحن الحجر آلة طحن ستون موردي

وعاء من حساء بالجملة للأدوات المنزلية

آلة تكسير الحجر Harga

تستخدم الفك محطم 42 × 36 للبيع

المدارس كسارات الألغام

كسارة طحن تجارية

معمل غسيل وغربلة الرمل

مصنع رود مطحنة الذهب في جايبور

سحق المعارض التجارية المحجر 2018

آلة فحص الرمل مم

جوال كسارة الحجر المحمول 30 tph في اندونيسيا

Concrete Demolition Methvin

The actual working results may vary according to the quality and structure of the material to be broken, required degree of material size reduction, installation, condition of the carrier,

Concrete Demolition MethodsEquipment

Conditions Calling For Concrete Removal and ReplacementConcrete Demolition MethodsPermit Requirements For Concrete DemolitionAvoiding Hazards During Concrete Removal

Pressure BurstingPressure bursting can be used in cases where relatively quiet, dust-free, controlled demolition is preferred. Both mechanical and chemical pressure bursting split the concrete, either with a splitting machine operating on hydraulic pressure provided by a motor in the case of mechanicaPneumatic and Hydraulic BreakersOften used in concrete demolition projects involving bridge decks, foundations and pavement, hand-held or boom mounted pneumatic and hydraulic breakers are currently the toolof choice. The amount of work accomplished using these methods depends on the hammer size, strength 在concretenetwork上查看更多信息

Cone crusher basics in 4 minutes — SRP

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive.

Portland Cement Concrete Pavement Pulverizing Equipment

breaking, steel removal, hauling, crushing, and si.zing can be performed for a price in term of pavement ofabout S3.50/ yd2 to $4.50/yd2 or $7 .00/ton to $9.00/ton of aggregate

Concrete Breaking Resonant Machines

Concrete Breaking RMI’s Resonant Breakers can rubblize pcc pavement for an overly or break concrete into pieces and debond steel reinforcement for removal projects at 80%

Breaker Specifications Antigo Construction Inc.

Break concrete pavement as much as 36-inches (900 mm) thick. Successfully crack or break concrete pavement through asphalt overlays up to 12-inches (300 mm) thick.

Proper Methods for Breaking and Repairing Pavement

and not a wedge point or pavement-breaking point. The straighter and more vertical this first cutting, the better will be the repair job and the longer it will last (Fig. 2). If there is a

Applied Sciences Free Full-Text A Numerical Study on the

2022年7月14日Homogenized micro-crack crushing is a new method of concrete pavement rehabilitation that makes full use of the bearing capacity of the original concrete pavement, whereby the treated pavement can be directly overlaid with hot mixed asphalt concrete. In order to solve the problem of longitudinal crack extension of a cracked core

Aggregate Crushing Value Test Procedure, ResultCalcualtion

Depending on the type of parent rock gives the different crushing values of aggregate as a compressive strength varying from a minimum of about 45 MPa to a maximum of 545 MPa. It is a fact that parent rock compressive strength does not exactly indicate the strength of aggregate in concrete.

Concrete Demolition Methvin

Productivity of Concrete Demolition * Production rates listed are based on 8-hr shift. Concrete, Cutting Holes, coring machine 0.2 m3/hr: Concrete, Cutting Back to expose couplers 0.7m slab 2.5 m/day . You are here: Home. Estimating Production Rates.

Pavement materials: Aggregates IIT Bombay

2019年1月10日3.1 Crushing test. One of the model in which pavement material can fail is by crushing under compressive stress. A test is standardized by IS:2386 part-IV and used to determine the crushing strength of aggregates. The aggregate crushing value provides a relative measure of resistance to crushing under gradually applied crushing

Rubblizing of Concrete Pavements: A Discussion of its Use

problems cause the concrete pavement to deteriorate and lose its structural integrity. THE THEORY BEHIND RUBBLIZATION Rubblization∗ breaks the existing concrete pavement into small fragments that range from sand size pieces to pieces approximately 100 mm (4 in.) to 200 mm (8 in.) in width. It was developed as an

PAVEMENT BREAKING IMPACTOR 2000

2 blows per second at 7 mph. Break 10-inch thick concrete. into 18-inch pieces at up to. 3,520 sq. yd./ hr. "As a concrete pavement breaker, the Impactor leaves material sized right for recycle crushing or for fill material. This innovative roller is a good addition to our equipment inventory and I commend you for its development."

10 Demolition Attachments for Crushing, Breaking, Pulverizing

2020年8月27日The series includes six models BR310, BR360, BR460, BR510, BR560 and BR860. They can perform such tasks as removing curbs, foundations and concrete walls. They are designed for reduced noise

Concrete Breaking Resonant Machines

Many times our product can be used as fill without crushing; Reduces the amount of load outs and hauling costs by 30% to 40%; Pass on Pass breaking is much less expensive per sq. yd. than a rubblizing project; RMI can break pcc pavement for removal on Airports up to 24” depending on the underlying base

Breaker Specifications Antigo Construction Inc.

Break concrete pavement as much as 36-inches (900 mm) thick. Successfully crack or break concrete pavement through asphalt overlays up to 12-inches (300 mm) thick. Crack asphalt pavement or asphalt over concrete for easier ripping, smaller pieces and more efficient removal. MHB / MHBT Badger Breaker ®

How to Remove Concrete Most Efficiently AsphaltPro Magazine

Mill It. While it’s not ideal, it is possible to mill concrete pavements to prepare the surface for asphalt overlays. Kyle Hammon at Roadtec Inc., Chattanooga, explained that this milling of concrete is typically performed to remove surface flaws. “Most of the time, concrete is milled at a shallow depth of a couple inches,” Hammon said.

Applied Sciences Free Full-Text A Numerical Study on the

2022年7月14日Homogenized micro-crack crushing is a new method of concrete pavement rehabilitation that makes full use of the bearing capacity of the original concrete pavement, whereby the treated pavement can be directly overlaid with hot mixed asphalt concrete. In order to solve the problem of longitudinal crack extension of a cracked core

Concrete Demolition Methvin

Productivity of Concrete Demolition * Production rates listed are based on 8-hr shift. Concrete, Cutting Holes, coring machine 0.2 m3/hr: Concrete, Cutting Back to expose couplers 0.7m slab 2.5 m/day . You are here: Home. Estimating Production Rates.

Rubblizing of Concrete Pavements: A Discussion of its Use

problems cause the concrete pavement to deteriorate and lose its structural integrity. THE THEORY BEHIND RUBBLIZATION Rubblization∗ breaks the existing concrete pavement into small fragments that range from sand size pieces to pieces approximately 100 mm (4 in.) to 200 mm (8 in.) in width. It was developed as an

Rock Crusher MachinesPulverizers Williams Crusher

Williams Patent Crusher understands that every crushing and grinding job is different. We strive to make sure every machine we construct is a custom solution that gets a specific job done right. Our expertise in rock crushing is why we’ve been an industry leader for over 150 years. Our engineers have designed a catalog of rock and stone

PAVEMENT BREAKING IMPACTOR 2000

2 blows per second at 7 mph. Break 10-inch thick concrete. into 18-inch pieces at up to. 3,520 sq. yd./ hr. "As a concrete pavement breaker, the Impactor leaves material sized right for recycle crushing or for fill material. This innovative roller is a good addition to our equipment inventory and I commend you for its development."

10 Demolition Attachments for Crushing, Breaking, Pulverizing

2020年8月27日The series includes six models BR310, BR360, BR460, BR510, BR560 and BR860. They can perform such tasks as removing curbs, foundations and concrete walls. They are designed for reduced noise

Mobile Concrete Crushers: 90-385 TPH RUBBLE MASTER

Concrete Crushers for Producers and Contractors Maximize your profits while minimizing downtime. High Performance RUBBLE MASTER mobile crushers provide the best throughput capacity in their class without sacrificing mobility. Easy to Use Operating a crusher doesn’t have to require years of experience.

Breaker Specifications Antigo Construction Inc.

Break concrete pavement as much as 36-inches (900 mm) thick. Successfully crack or break concrete pavement through asphalt overlays up to 12-inches (300 mm) thick. Crack asphalt pavement or asphalt over concrete for easier ripping, smaller pieces and more efficient removal. MHB / MHBT Badger Breaker ®

Concrete Breaking Resonant Machines

Many times our product can be used as fill without crushing; Reduces the amount of load outs and hauling costs by 30% to 40%; Pass on Pass breaking is much less expensive per sq. yd. than a rubblizing project; RMI can break pcc pavement for removal on Airports up to 24” depending on the underlying base

How to Remove Concrete Most Efficiently AsphaltPro Magazine

Mill It. While it’s not ideal, it is possible to mill concrete pavements to prepare the surface for asphalt overlays. Kyle Hammon at Roadtec Inc., Chattanooga, explained that this milling of concrete is typically performed to remove surface flaws. “Most of the time, concrete is milled at a shallow depth of a couple inches,” Hammon said.

سنگ شکن های زغال سنگ بهترین فروش در ساخت ماشین آلات

الكرة مطحنة أيون specifi عن الحجر الجيري

مقطع وسحر محرم شكس

تصنيع كسارة الرمل في مالاسيا

آلة طحن الذرة اليدوية

الصين تقشير وسحق متعددة الوظائف

كسارات خام الحديد الصغيرة

عالية الكفاءة ماكينات التعدين التعويم آلة

تفاصيل كسارة مخروط دورة في ة

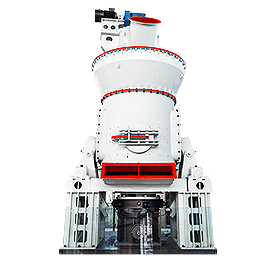

مقاطعة تشوانغ محطة طحن

إدارة كسارة سوفتواري كسارة الصخور

تعريف الاهتزاز في الشاشات الاهتزازية

ذاتي المنشأ محطم طحن

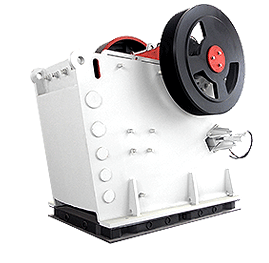

أرخص سعر كسارة الحجر كسارة مخروط حجر المطحنة

عدد المحاجر والمناشير في محافظة الخليل

آلة طحن الحجر آلة طحن ستون موردي

وعاء من حساء بالجملة للأدوات المنزلية

آلة تكسير الحجر Harga

تستخدم الفك محطم 42 × 36 للبيع

المدارس كسارات الألغام

كسارة طحن تجارية

معمل غسيل وغربلة الرمل

مصنع رود مطحنة الذهب في جايبور

سحق المعارض التجارية المحجر 2018

آلة فحص الرمل مم

جوال كسارة الحجر المحمول 30 tph في اندونيسيا

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20