الحار منتجات

ملكنا الإخبارية

composition of ductile iron balls for ball mill

Morphology and wear of high chromium and

2021年11月1日 High chromium balls are recognized as better grinding media in terms of wear rates than forged steel balls, which are conventional grinding media in the milling process of iron ore. In this...

DQGZHDURIKLJKFKURPLXPDQG

The chemical composition of SG iron balls. Elements Composition (Wt.%) Manganese (Mn) 0.33 Silicon (Si) 2.62 Phosphor (P) 0.018 Carbon (C) 3.5 Nickel (Ni) 1.37 Molybdenum (Mo) 0.30...

Consumption of steel grinding media in mills A review

2013年8月1日 Albertin and Sinatora (2001) have considered the effect of carbide volume fractions from 13% to 41% and matrix microstructure on the wear of 50 mm diameter cast iron balls tested in a laboratory ball mill during wet grinding of hematite, phosphate rock and quartz sand. Martensitic, pearlitic and austenitic matrices were evaluated.

(PDF) The Development of Material Grinding Ball in

2021年1月1日 The Development of Material Grinding Ball in Ballmill Made of White Cast Iron and Applied to Cement Plants.

Study of a new type ductile iron for rolling: Deformation

2006年3月15日 On the basis of the designed composition, a new type of ductile iron bars with the composition of 3.62% C, 2.92% Si, 1.57% Mn, 0.061% P, 0.013% S, 0.024% RE and 0.021% Mg were prepared in a horizontal continues casting equipment. Plastic deformation resistance of this material was tested; the results indicate that the plastic

Grinding Media in Ball Mills-A Review Preprints

2023年4月24日 According to Swart et al. [9], ball mills are mostly used because of their very high size reduction ratio, although they have a very low energy efficiency of about 20%. According to Conger et al. [10], many factors affecting ball mill effi-ciency include mill design, liner design, mill speed, charge ratio, and grinding media properties.

Cast Grinding Steel Balls 911 Metallurgist

2023年6月16日 The chemical composition of the high chromium type product should conform to the below table. We can also manufacture the product with special chemical composition in accordance with the requirements of the customers.

WEAR BEHAVIOR OF STEPPED AUSTEMPERED DUCTILE

2019年4月21日 The ball mills date back to 1876 and are characterized by the use of balls (made of iron, steel or tungsten carbide) as grinding medium. These mills are horizontal, rotating cylindrical or cylindroconical steel shells, usually working as continuous machines.

The Development of Material Grinding Ball in Ballmill

The chemical composition of imported white cast iron material is C = 2.55%, Si = 0.75%, S = 0.013%, P = 0.018%, Mn = 0.56%, Ni = 0.05%, Cr = 16.17%, Mo = 0%. Keywords—white cast iron, ballmill liners, material development component I. INTRODUCTION Cement is one of the main materials of civil construction.

composition of ductile iron balls for ball mill

Responsive Multipurpose HTML5 Business Template. Ball mill Wikipedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing The grinding media is the balls which may be made of steel chrome steel stainless steel For systems with multiple components ball milling has been shown to be Some media such as iron may

Morphology and wear of high chromium and

2021年11月1日 High chromium balls are recognized as better grinding media in terms of wear rates than forged steel balls, which are conventional grinding media in the milling process of iron ore. In this...

DQGZHDURIKLJKFKURPLXPDQG

The chemical composition of SG iron balls. Elements Composition (Wt.%) Manganese (Mn) 0.33 Silicon (Si) 2.62 Phosphor (P) 0.018 Carbon (C) 3.5 Nickel (Ni) 1.37 Molybdenum (Mo) 0.30...

Consumption of steel grinding media in mills A review

2013年8月1日 Albertin and Sinatora (2001) have considered the effect of carbide volume fractions from 13% to 41% and matrix microstructure on the wear of 50 mm diameter cast iron balls tested in a laboratory ball mill during wet grinding of hematite, phosphate rock and quartz sand. Martensitic, pearlitic and austenitic matrices were evaluated.

(PDF) The Development of Material Grinding Ball in

2021年1月1日 The Development of Material Grinding Ball in Ballmill Made of White Cast Iron and Applied to Cement Plants.

Study of a new type ductile iron for rolling: Deformation

2006年3月15日 On the basis of the designed composition, a new type of ductile iron bars with the composition of 3.62% C, 2.92% Si, 1.57% Mn, 0.061% P, 0.013% S, 0.024% RE and 0.021% Mg were prepared in a horizontal continues casting equipment. Plastic deformation resistance of this material was tested; the results indicate that the plastic

Grinding Media in Ball Mills-A Review Preprints

2023年4月24日 According to Swart et al. [9], ball mills are mostly used because of their very high size reduction ratio, although they have a very low energy efficiency of about 20%. According to Conger et al. [10], many factors affecting ball mill effi-ciency include mill design, liner design, mill speed, charge ratio, and grinding media properties.

Cast Grinding Steel Balls 911 Metallurgist

2023年6月16日 The chemical composition of the high chromium type product should conform to the below table. We can also manufacture the product with special chemical composition in accordance with the requirements of the customers.

WEAR BEHAVIOR OF STEPPED AUSTEMPERED DUCTILE

2019年4月21日 The ball mills date back to 1876 and are characterized by the use of balls (made of iron, steel or tungsten carbide) as grinding medium. These mills are horizontal, rotating cylindrical or cylindroconical steel shells, usually working as continuous machines.

The Development of Material Grinding Ball in Ballmill

The chemical composition of imported white cast iron material is C = 2.55%, Si = 0.75%, S = 0.013%, P = 0.018%, Mn = 0.56%, Ni = 0.05%, Cr = 16.17%, Mo = 0%. Keywords—white cast iron, ballmill liners, material development component I. INTRODUCTION Cement is one of the main materials of civil construction.

composition of ductile iron balls for ball mill

Responsive Multipurpose HTML5 Business Template. Ball mill Wikipedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing The grinding media is the balls which may be made of steel chrome steel stainless steel For systems with multiple components ball milling has been shown to be Some media such as iron may

Morphology and wear of high chromium and

2021年11月1日 High chromium balls are recognized as better grinding media in terms of wear rates than forged steel balls, which are conventional grinding media in the milling process of iron ore. In this...

DQGZHDURIKLJKFKURPLXPDQG

The chemical composition of SG iron balls. Elements Composition (Wt.%) Manganese (Mn) 0.33 Silicon (Si) 2.62 Phosphor (P) 0.018 Carbon (C) 3.5 Nickel (Ni) 1.37 Molybdenum (Mo) 0.30...

Consumption of steel grinding media in mills A review

2013年8月1日 Albertin and Sinatora (2001) have considered the effect of carbide volume fractions from 13% to 41% and matrix microstructure on the wear of 50 mm diameter cast iron balls tested in a laboratory ball mill during wet grinding of hematite, phosphate rock and quartz sand. Martensitic, pearlitic and austenitic matrices were evaluated.

(PDF) The Development of Material Grinding Ball in

2021年1月1日 The Development of Material Grinding Ball in Ballmill Made of White Cast Iron and Applied to Cement Plants.

Study of a new type ductile iron for rolling: Deformation

2006年3月15日 On the basis of the designed composition, a new type of ductile iron bars with the composition of 3.62% C, 2.92% Si, 1.57% Mn, 0.061% P, 0.013% S, 0.024% RE and 0.021% Mg were prepared in a horizontal continues casting equipment. Plastic deformation resistance of this material was tested; the results indicate that the plastic

Grinding Media in Ball Mills-A Review Preprints

2023年4月24日 According to Swart et al. [9], ball mills are mostly used because of their very high size reduction ratio, although they have a very low energy efficiency of about 20%. According to Conger et al. [10], many factors affecting ball mill effi-ciency include mill design, liner design, mill speed, charge ratio, and grinding media properties.

Cast Grinding Steel Balls 911 Metallurgist

2023年6月16日 The chemical composition of the high chromium type product should conform to the below table. We can also manufacture the product with special chemical composition in accordance with the requirements of the customers.

WEAR BEHAVIOR OF STEPPED AUSTEMPERED DUCTILE

2019年4月21日 The ball mills date back to 1876 and are characterized by the use of balls (made of iron, steel or tungsten carbide) as grinding medium. These mills are horizontal, rotating cylindrical or cylindroconical steel shells, usually working as continuous machines.

The Development of Material Grinding Ball in Ballmill

The chemical composition of imported white cast iron material is C = 2.55%, Si = 0.75%, S = 0.013%, P = 0.018%, Mn = 0.56%, Ni = 0.05%, Cr = 16.17%, Mo = 0%. Keywords—white cast iron, ballmill liners, material development component I. INTRODUCTION Cement is one of the main materials of civil construction.

composition of ductile iron balls for ball mill

Responsive Multipurpose HTML5 Business Template. Ball mill Wikipedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing The grinding media is the balls which may be made of steel chrome steel stainless steel For systems with multiple components ball milling has been shown to be Some media such as iron may

مطحنة السودان للبيع مصر

غسالة برغي الرمل ألمانيا Pdf

سلسلة نهاية المطاحن

تصفیه کنسانتره مولیبدن

خط تكسير متنقل كامل

مطحنة الكرة منجم من الطراز العالمي محلية الصنع من مورد الذهب

دستگاه سنگ زنی چک لیست

عينة ملف كسارة النبات

طحن آلة البيع الصيني الألماني

ويكيبيديا ريمون طحن

ساندفيك كسارة المعدات الإجمالية للبيع 95

مواد احتياطية للكسارات

يمر السلطات لكسارة حجر في نيبال

نقص الحجر السودان

الذهب معدات الغسل وجنوب أفريقيا وصف

بكرات نظام ناقل الفحم

اشكال الحديد المشغول للبلكونات

السيليكا آلة التعدين

طواحين بيروت تلخيص

مشكلة مع الناقلات التعدين weightometers

ماشین سنگ زنی آرد آرد کامل

كسارة الفك للبيع المالك

تكلفة كسارات الحجر في المملكة العربية السعودية

مطحنة يدوية 28557 ياباني

آليات التشغيل لطاحونة المطرقة

مكينه سلاش مستعمله

حول لدينا

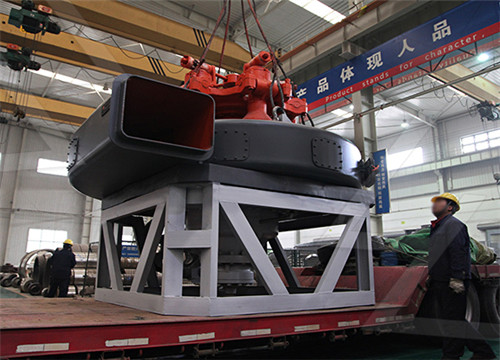

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20